filmov

tv

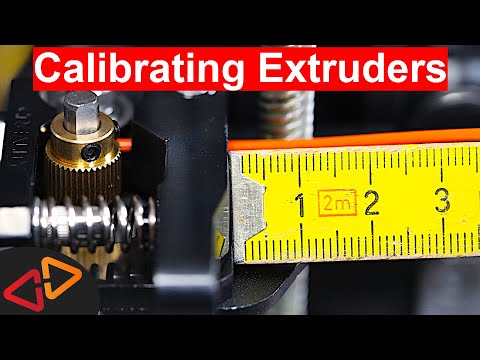

Extruder Calibration Cura

Показать описание

I created a video to calibrate the E steps on 3d printers using Cura on my Anycubic Kobra Go. Just thought it might be helpful for anyone that doesn't want to use Pronterface. I tried to keep it simple, let me know what you think.

Some PLA filaments that I've used

Remember anything following ; is purely a note, not executable code.

;FLAVOR:Marlin

;Generated with Cura_SteamEngine 5.2.1

M92 E95.00 ; after testing you will change 95 to your test result value

M104 S200 ; set hot end temp

M105 ; report temp

M109 S200 ; wait for hot end temp

M82 ;absolute extrusion mode

G92 E0 ; Reset Extruder

G28 ; Home all axes

G1 E100 F100

M84 X Y Z ;Disable all steppers but E

M104 S0 ; switch off hot end

;End of Gcode

Some PLA filaments that I've used

Remember anything following ; is purely a note, not executable code.

;FLAVOR:Marlin

;Generated with Cura_SteamEngine 5.2.1

M92 E95.00 ; after testing you will change 95 to your test result value

M104 S200 ; set hot end temp

M105 ; report temp

M109 S200 ; wait for hot end temp

M82 ;absolute extrusion mode

G92 E0 ; Reset Extruder

G28 ; Home all axes

G1 E100 F100

M84 X Y Z ;Disable all steppers but E

M104 S0 ; switch off hot end

;End of Gcode

Extruder Calibration Cura

E-Step Calibration of a 3D Printer Extruder

Easiest Way to Calibrate E-Steps on 3D Printer with a Bowden Tube | Extruder Calibration Ender 3 Pro

Calibrating 3d Printer Flow Rate with Cura - The Quick Fix for Under Extrusion

Calibrate Perfect Retraction Settings Using a Cura 4.8 Plug-in

EXTRUDER KALIBRIEREN 3D Drucker - TUTORIAL [E-Steps]

Fix Under Extrusion With Extruder Calibration (Estep)

Extruder Kalibrieren | Tutorial | E-Steps einstellen für perfekte Druckergebnisse

Ender 3v2 - How to Calibrate E-Steps (Quick & Easy)

Cura Settings for Retraction and Raft on Creality Ender 3 or CR-10 Mini

3D Printer Extruder Calibration

Getting the Right Flow: Ultimaker Cura 5 Flow Rate Settings

CALIBRATING EXTRUDERS - Why and how to do it

How To Tune The Flow Rate On Your 3D Printer!

3D Printer Extruder Calibration|How To Calibrate Your 3D Printers Extruder Esteps

Tuning Material Flow For Best Quality 3d Prints (OrcaSlicer)

Stringing Nightmares: How Cura's Travel Settings Can Save 3D Prints

The Ultimate Guide to Perfect 3D Prints

ESteps calibration in 2 min on Ender 3 V3 SE direct drive extruder

How TO Calibrate The Esteps On A Direct Drive Extruder The EASY Way!

E Step Calibration Vs Flow

3D printer calibration revolutionised - Step by step to better print quality

How To Calibrate E-steps and Flow Rate for Ender 3

Tuning Pressure Advance Has Never Been Easier (OrcaSlicer Calibration)

Комментарии

0:16:06

0:16:06

0:04:37

0:04:37

0:10:26

0:10:26

0:06:27

0:06:27

0:07:48

0:07:48

0:10:30

0:10:30

0:15:27

0:15:27

0:06:46

0:06:46

0:03:08

0:03:08

0:05:39

0:05:39

0:09:10

0:09:10

0:35:28

0:35:28

0:08:31

0:08:31

0:07:42

0:07:42

0:15:42

0:15:42

0:11:51

0:11:51

0:37:07

0:37:07

0:17:27

0:17:27

0:02:46

0:02:46

0:09:09

0:09:09

0:09:24

0:09:24

0:19:28

0:19:28

0:08:10

0:08:10

0:07:21

0:07:21