filmov

tv

Structural steel fabrication Beam fit up and Mig Welding. GMAW

Показать описание

Structural steel Beam fit up and Mig Welding.

GMAW

Structural steel Fabrication

Mig welding GMAW

Stick welding

Steel work

Metal work

Structural steel work

Workshop

Steel Fabrication

Welding

Magnetic drill

Machine

Tube notching

Tube machine tube coping

Geka metalworker

Mig welder

Bosch Mini angle grinder

Engineers Square

Hammer

Chalk

Stanley measuring tape

Esab welding screen

Miller

Tig welding

I beam

Steel beam

Universal beam

Rsj

Cast iron

Mild steel

Box tube

Plate

Flap disc

Band saw

Splice straight line connection

Galvanized steel

Galvanised steel

Cope mitre joint

GMAW

Structural steel Fabrication

Mig welding GMAW

Stick welding

Steel work

Metal work

Structural steel work

Workshop

Steel Fabrication

Welding

Magnetic drill

Machine

Tube notching

Tube machine tube coping

Geka metalworker

Mig welder

Bosch Mini angle grinder

Engineers Square

Hammer

Chalk

Stanley measuring tape

Esab welding screen

Miller

Tig welding

I beam

Steel beam

Universal beam

Rsj

Cast iron

Mild steel

Box tube

Plate

Flap disc

Band saw

Splice straight line connection

Galvanized steel

Galvanised steel

Cope mitre joint

Structural Steel Fabrication - Marking out & Tacking end cap plate to steel beam. Part 1

Structural steel fabrication Beam fit up and Mig Welding. GMAW

Meet Nix | Structural Fabrication Division

Structural steel fabrication - Basic and essential methods of marking out steel beams,RSJ & Colu...

Introducing: the Voortman Fabricator - automated fitting and full-welding for steel fabricating

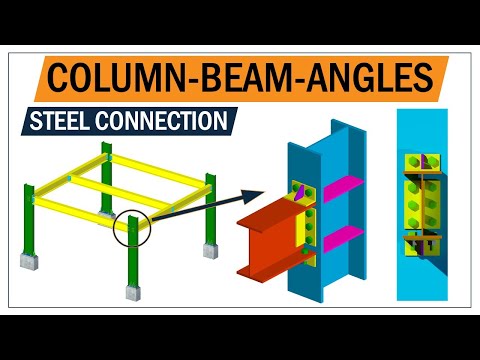

Steel connection | beam to Column shear & moment connection | Bolted connections | Greyspace

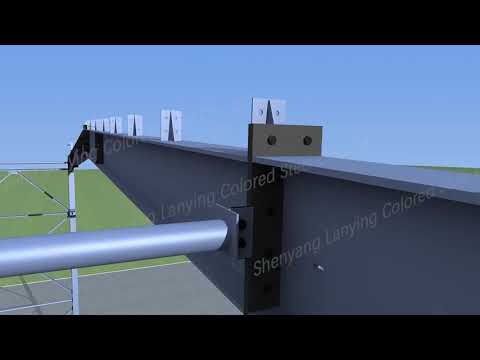

Steel Structure Installation Instruction-2.2Install steel column

Beam, Column- Squaring tutorial for fitters. structural fabrication tips and tricks.

Steel structure installation guidance 3D animation

What are the Different Structural Steel Shapes?

how to marking and fitting plate in beam steel Fabrication full videos

How to Mark out and notch steel beams - Structural steel work fabrication. 9”angle grinder

Structural Steel beam flange plate connection. Steel fabrication & Mig welding.

How to do a steel beam calculation

HOW TO INSTALL STEEL BEAMS *PROPERLY*

How to read steel structural beam fabrication drawing in (English)

Fabrication process of steel building frame and the fully automatic steel frame welding line

Beam to Beam Steel Connection | Bolted connections | shear connections | steel fabrication | 3d

Structural Steel Frame Anatomy and Process

VIP Structural Steel Workshop Tour Bay 2 & 0, Bromley Christchurch

The Critical Weakness of the I-Beam

ARCMAN™ Structural Steel Welding Robot System with FCAW (Seismic Application)

🤩steel structure building 🔥height work#shorts#column#erection #factory #viral

How to do Fit Up Structural Steel Fabrication

Комментарии

0:03:01

0:03:01

0:10:01

0:10:01

0:02:35

0:02:35

0:07:01

0:07:01

0:02:57

0:02:57

0:03:43

0:03:43

0:01:21

0:01:21

0:03:04

0:03:04

0:04:08

0:04:08

0:18:35

0:18:35

0:02:54

0:02:54

0:03:03

0:03:03

0:10:55

0:10:55

0:11:32

0:11:32

0:01:19

0:01:19

0:05:40

0:05:40

0:11:03

0:11:03

0:07:29

0:07:29

0:05:43

0:05:43

0:02:19

0:02:19

0:06:14

0:06:14

0:06:11

0:06:11

0:00:51

0:00:51

0:08:09

0:08:09