filmov

tv

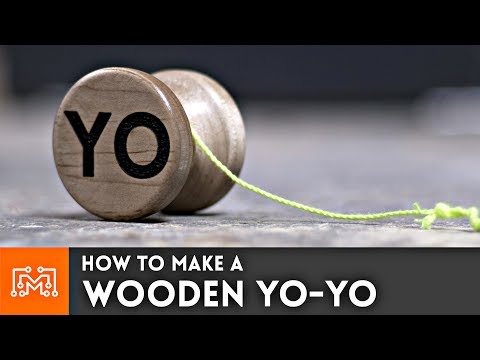

How to Make a Wooden Yo-Yo (with a bearing) // Woodworking

Показать описание

Recently I got to take a 30 minute yo-yo class from a couple of professional yo-yoers and it opened my eyes to how much fun (and how accessible) it was. I immediately started thinking of how to make a yo-yo and since I still need lots of practice on my lathe, I figured I'd give it a try.

I added bearing to my yo-yo and as a first try, it worked pretty well. I learned a lot and hope to turn another yo-yo soon building in the feedback from commenters.

Some other yo-yo builds I found:

TOOLS LIST:

(some are better than the versions I own)

Learn 3d modeling, get digital plans, and cool merch at

Want to support ILTMS? Get exclusive content and more...

FOLLOW:

#ILikeToMakeStuff

About I Like To Make Stuff:

We have lots of projects including woodworking, metalworking, electronics, 3D printing, prop making and more!

These videos are our attempt inspire and empower others to make the stuff that they want to have. Hopefully you'll see something here that will inspire you to make something that you're passionate about!

How to make a wooden Yo-yo (with a bearing) // Woodworking | I Like To Make Stuff

I Like To Make Stuff

I added bearing to my yo-yo and as a first try, it worked pretty well. I learned a lot and hope to turn another yo-yo soon building in the feedback from commenters.

Some other yo-yo builds I found:

TOOLS LIST:

(some are better than the versions I own)

Learn 3d modeling, get digital plans, and cool merch at

Want to support ILTMS? Get exclusive content and more...

FOLLOW:

#ILikeToMakeStuff

About I Like To Make Stuff:

We have lots of projects including woodworking, metalworking, electronics, 3D printing, prop making and more!

These videos are our attempt inspire and empower others to make the stuff that they want to have. Hopefully you'll see something here that will inspire you to make something that you're passionate about!

How to make a wooden Yo-yo (with a bearing) // Woodworking | I Like To Make Stuff

I Like To Make Stuff

Комментарии

0:10:48

0:10:48

0:07:14

0:07:14

0:14:02

0:14:02

0:10:12

0:10:12

0:09:19

0:09:19

0:08:33

0:08:33

0:20:51

0:20:51

0:09:43

0:09:43

0:09:43

0:09:43

0:10:53

0:10:53

0:11:54

0:11:54

0:12:23

0:12:23

0:24:35

0:24:35

0:08:44

0:08:44

0:10:44

0:10:44

0:15:17

0:15:17

0:16:20

0:16:20

0:11:03

0:11:03

0:05:22

0:05:22

0:08:57

0:08:57

0:10:44

0:10:44

0:07:50

0:07:50

0:07:38

0:07:38

0:18:33

0:18:33