filmov

tv

I tried Injection Molding using a 3D Printer!

Показать описание

I wanted to find out if I can use a 3D printer as an injection molding machine. I printed molds using resin and then injected the molten plastic using a hotend. But how well did it work, what are the limitations and what could this method be useful for? Let's find out more!

💚 Support me 🙏

Join as a YouTube member!

*Chapters*

00:00 Introduction

01:11 Making a Mold

04:25 Sponsor

05:48 1st Attempt: PLA

07:31 High-Speed PLA

08:30 Why all of this?

09:42 Mold Pre-Heating

11:53 Switching Printers

15:25 Injection Molding with TPU

16:08 Building the Über-Extruder

17:39 Summary

#3Dprinting #DIY #injectionmolding

DISCLAIMER: Part of this video was sponsored by KiwiCo.

FTC Disclaimer: A percentage of sales is made through Affiliate links

I tried Injection Molding using a 3D Printer!

3D Printed Injection Molds (actually work)!

Another 3D Printed Injection MOLDING TOOL test.

3D Printed vs Aluminum Injection Molds

First time INJECTION MOLDING! | Bench-top plastic injection molding.

Injection Moulding Made Easy | Precious Plastic Melbourne

Skip injection molding and try MJF 3D printing!

What happen?! When the injection molding workshop meets AI!!Let's try together?

Unbreakable PNW Mountain Cup Set by NORTH DRINKWARE

Recycling Plastic with Injection Molding

Plastic Injection Molding

5 Tips to Avoid Expensive Plastic Injection Molding Mistakes | Serious Engineering: Ep30

3D Printing & Injection Molding IMPOSSIBLE Parts? Nexa3D at Formnext 2023!

What is Injection Molding and How Does it Work?

An injection mold made from RESIN and METAL powder.

Injection Molding - Design Your Product for Manufacturing

Making Larger Injection Molded Parts

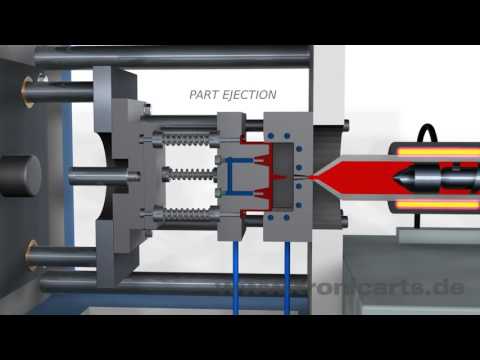

Injection Molding Animation

Plastic Injection Molding

Injection Molding a Spoon - Designing, making, using

Injection molding machine adjustment is really a technical job that requires experience

This is a one out of two mold design injection molding process

How do the sliders(slide) work in plastic injection mold?

How to make plastic products | Plastic Injection Molding | Plastic industry|Making Plastic Items.

Комментарии

0:18:27

0:18:27

0:20:53

0:20:53

0:00:25

0:00:25

0:25:04

0:25:04

0:17:17

0:17:17

0:00:27

0:00:27

0:00:23

0:00:23

0:00:07

0:00:07

0:02:29

0:02:29

0:03:33

0:03:33

0:09:37

0:09:37

0:08:23

0:08:23

0:12:53

0:12:53

0:05:21

0:05:21

0:15:14

0:15:14

0:13:55

0:13:55

0:15:25

0:15:25

0:02:59

0:02:59

0:01:35

0:01:35

0:23:52

0:23:52

0:00:06

0:00:06

0:00:08

0:00:08

0:00:26

0:00:26

0:00:14

0:00:14