filmov

tv

How parallel does it cut?

Показать описание

After restoring this Celtic 14 lathe, I would like to know if it cuts cylinders or tapers. Let's do the test.

How parallel does it cut?

Angle Grinder Caution !!! #Shorts

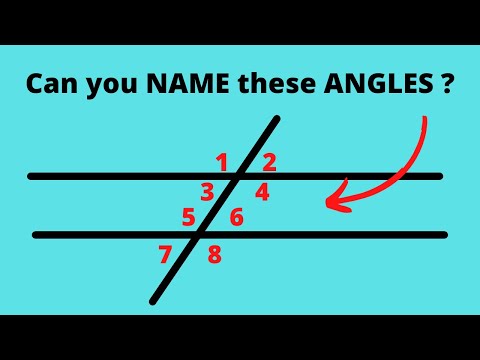

Parallel Lines cut by a Transversal

How To: Easy Parallel Parking

How to judge the distance around the car #carsafety #mechancial #car #tips #driving #carsoft

How to Parallel Park #parallelparking #parking #parkingtips #drivingtest #parallelparkingtips #cars

The Spring Paradox

What if we add 2200uF Capacitor in series with speaker !?

Sections of Solids Solutions - Hexagonal Pyramid - Computer Aided Engineering Drawing

Fuse #shorts

How to Aim Tough Cut Shot Parallel Aiming System #billiards #poolplayer #8ballpool #9ball

9V battery lifehack tricks #tricks #lifehacks

Mastering Reverse Parking: Tips for All Vehicle Types #cardrivingtips #automobile #shorts

GCSE Maths - Alternate, Corresponding and Allied Angles - Parallel Lines Angle Rules

Hack To Trim Your Hair at home✂️ #trimmer #hairtutorial #hairtransformation

experiment with capacitor #shorts

Parallel Lines Cut by a Transversal & Angle Relationships!

Astar pant plazo cutting #shots

3 contemporary/lyrical turns for beginner-intermediate dancers

How to shorten your jeans ❌without sewing❌ Save for later! 👀 Daily #shorts about #fashionhacks...

Differences Between Taper Tip & Parallel Tip Iron Shafts

Parallel Parking #parallelparking #drivingtips #howtoparallelpark #parallelparkingtips #drivingtest

Life Doodles | Sausage is cut into ice creams #lifedoodles #shorts #animation #cartoon

Keep sharing the best parking skills with you!#car #driving #drivingtest

Комментарии

0:21:09

0:21:09

0:00:22

0:00:22

0:02:36

0:02:36

0:01:17

0:01:17

0:00:56

0:00:56

0:00:47

0:00:47

0:09:30

0:09:30

0:00:16

0:00:16

0:22:40

0:22:40

0:00:21

0:00:21

0:00:32

0:00:32

0:00:20

0:00:20

0:00:25

0:00:25

0:05:36

0:05:36

0:00:21

0:00:21

0:00:22

0:00:22

0:09:35

0:09:35

0:00:16

0:00:16

0:00:12

0:00:12

0:00:11

0:00:11

0:03:29

0:03:29

0:01:00

0:01:00

0:00:12

0:00:12

0:00:21

0:00:21