filmov

tv

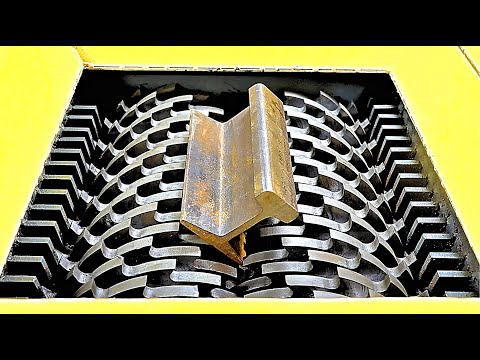

$50 DIY shredder to Crush recycling from 3D printer parts ABS or PLA

Показать описание

If you want to buy some parts in this video, you can check my website

Playlist of videos related to this project

STL files that can be used for 3D printing can be downloaded from here

Bill of materials

18 pcs stainless steel blades cost $50

Other parts are made by myself or Recycling on old machines

Frame uses CNC engraving machine to cut 10MM PVC sheet;

16MM hexagonal steel shaft;

6003 inner six corner bearing;

30:1 worm gearbox;

200W hand drill;

Wooden base;

The shredder in this video is just right,

But it can't crush larger plastic,

It uses PVC plate as the bearing seat,

It will break under more powerful conditions, so steel must be used.

The old worm reducer in the video can't withstand the greater torque either.

The blade must be sharpened to reduce motor power.

There are still many areas that need improvement.

Want to get a reliable shredder,

The actual cost time is much higher.

If you want to make it , I recommend you watching my videos playlist .

Playlist of videos related to this project

STL files that can be used for 3D printing can be downloaded from here

Bill of materials

18 pcs stainless steel blades cost $50

Other parts are made by myself or Recycling on old machines

Frame uses CNC engraving machine to cut 10MM PVC sheet;

16MM hexagonal steel shaft;

6003 inner six corner bearing;

30:1 worm gearbox;

200W hand drill;

Wooden base;

The shredder in this video is just right,

But it can't crush larger plastic,

It uses PVC plate as the bearing seat,

It will break under more powerful conditions, so steel must be used.

The old worm reducer in the video can't withstand the greater torque either.

The blade must be sharpened to reduce motor power.

There are still many areas that need improvement.

Want to get a reliable shredder,

The actual cost time is much higher.

If you want to make it , I recommend you watching my videos playlist .

Комментарии

0:07:35

0:07:35

0:25:25

0:25:25

0:11:22

0:11:22

0:14:02

0:14:02

0:15:48

0:15:48

0:00:14

0:00:14

0:00:13

0:00:13

0:01:18

0:01:18

0:00:43

0:00:43

0:00:20

0:00:20

0:00:21

0:00:21

0:10:18

0:10:18

0:12:37

0:12:37

0:00:30

0:00:30

0:00:59

0:00:59

0:00:27

0:00:27

0:02:05

0:02:05

0:10:06

0:10:06

0:00:15

0:00:15

0:00:08

0:00:08

0:03:16

0:03:16

0:00:50

0:00:50

0:03:47

0:03:47

0:06:27

0:06:27