filmov

tv

plastic waste to oil/fuel improved pyrolysis reactor

Показать описание

hello you all

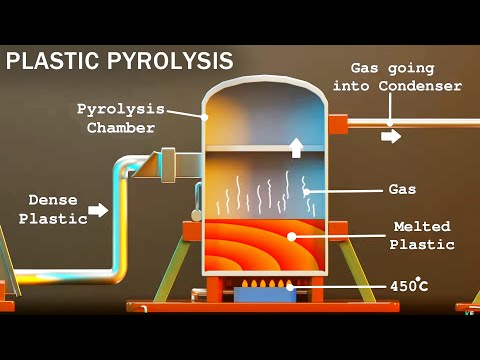

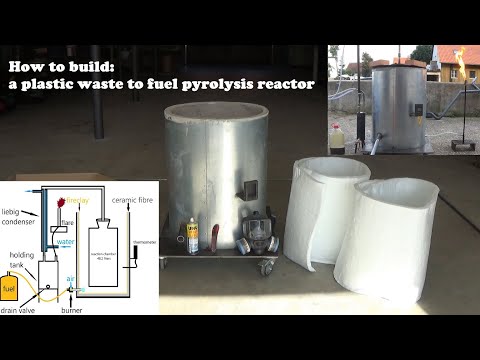

in this video i will show you my improved pyrolysis reactor which pyrolyticly turns plastic waste into combustable gases and pyrolysis oil, this oil can be refined into gasoline and diesel

this video is only a test run of the system without measuring the gas consumption or the weight of the used plastic. exact data will be collected for the next video! but the process will be explained in this video and also how to build such a reactor.

in this video i will show you my improved pyrolysis reactor which pyrolyticly turns plastic waste into combustable gases and pyrolysis oil, this oil can be refined into gasoline and diesel

this video is only a test run of the system without measuring the gas consumption or the weight of the used plastic. exact data will be collected for the next video! but the process will be explained in this video and also how to build such a reactor.

plastic waste to oil/fuel improved pyrolysis reactor

How Waste Plastic is Converted into Fuel | Plastic Pyrolysis | Karthi Explains

Turning waste plastic into Petrol | The Better India

Plastic to Fuel | Using Waste Oil Burner to distill into Petrol

how to make a plastic waste to fuel pyrolysis reactor

Plastic to fuel - Make fuel from plastic waste

Techie turning plastic to fuel

Recycling Waste Plastics into Fuel Oil, using Pyrolysis Technology by FSK Builders

Conversion of Plastic into Fuel Oil through Pyrolysis by Prof. Srinivas Seethamraju

Meet PETROL MAN! Man who makes Petrol out of Waste Plastic! 🔥

Plastic to fuel - Make fuel from plastic waste. Upgraded the 'catch can' [Episode 4]

Waste Plastic to Fuel | Waste to Diesel Process (2022)

How to make gas out of plastic waste

Plastic Waste To Fuel Oil and Gas | Pyrolysis | P2O

Microwaves are the best way to turn plastic waste into fuel! ⚡️ 🔥 ⛽️ #Naturejab #Science #education...

Do you know how to convert waste plastic/tyres to fuel oil ? get most profits in least money?

Investigation of Chemical Properties of Pyrolysis Oil Extracted from Waste Plastics

Plastic Waste to FUEL Explained {Future Friday Ep89}

Turning Waste Plastic into Fuel Oil - Plastic Pyrolysis Machine

Waste plastic to fuel oil pyrolysis plant project installed by DOING

Small Plastic Waste Recycling To Fuel Oil Machine Price Pyrolysis Plant

Eco India: Could a fuel generated from plastic waste replace fossil fuels and meet energy needs?

Turning plastic waste into fuel with @naturejab

How much does a plastic waste to fuel project cost?

Комментарии

0:06:38

0:06:38

0:04:40

0:04:40

0:01:57

0:01:57

0:08:59

0:08:59

0:12:46

0:12:46

0:11:18

0:11:18

0:00:59

0:00:59

0:05:46

0:05:46

0:50:04

0:50:04

0:01:00

0:01:00

0:08:30

0:08:30

0:01:58

0:01:58

0:00:45

0:00:45

0:02:55

0:02:55

0:01:01

0:01:01

0:00:31

0:00:31

0:15:03

0:15:03

0:19:09

0:19:09

0:03:50

0:03:50

0:00:41

0:00:41

0:00:46

0:00:46

0:13:55

0:13:55

0:00:32

0:00:32

0:01:07

0:01:07