filmov

tv

See the difference between soldering paste and resin. Soldering paste makes iron solder, not resin.

Показать описание

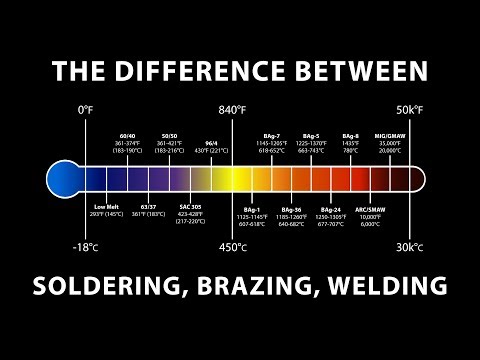

The Difference Between Soldering, Brazing, and Welding - Solder Series: Ep. 2

See the difference between soldering paste and resin. Soldering paste makes iron solder, not resin.

The Difference Between Tin and Lead in Solder Wire – Expert Soldering for Electronic Components

What´s the Difference between Soldering and Welding? | Soldering vs. Brazing vs. Welding | Soldering...

Welding vs Soldering vs Brazing - Basic Brazing Tutorial

Soldering Crash Course: Basic Techniques, Tips and Advice!

Soldering Station Vs. Soldering Iron Which is beter?

What Type of Solder Should you use.

[Beginner Must-See!]The Configuration of Soldering Robot

Leaded vs. Lead-Free Solder Wire: How Tin Content Impacts Your Soldering Results!

Brazing/Soldering

The difference between soldering with and without flux.

Solder wire - Low vs High Quality

Differences between Soldering and Brazing.

Difference between #Welding and #Brazing and #Soldering

How To Use Solder Paste | Short Video #soldering #shorts

Soldering tips and tricks - Tip 11 Use the right quantity of solder and temperature when soldering!

Differences between soldering and welding #shorts

Differences between Soldering and Brazing - Mechanical Engineering

Does anyone know the difference between rosin and solder paste #solderingpaste #welding

Soldering Brazing and Welding Difference || Difference between soldering brazing and welding

THERMAL CAMERA Imaging of Soldering Vs Spot-Welding 18650 cells

Difference Between - Soldering, Brazing, Braze Welding - Welding Process - Production Process 1

Mastering Rosin Soldering Paste: Lead-Free Flux for Quick and Easy Repairs

Комментарии

0:02:12

0:02:12

0:00:26

0:00:26

0:00:32

0:00:32

0:03:13

0:03:13

0:09:19

0:09:19

0:16:11

0:16:11

0:03:37

0:03:37

0:02:12

0:02:12

![[Beginner Must-See!]The Configuration](https://i.ytimg.com/vi/zKWpdjN_Orc/hqdefault.jpg) 0:02:34

0:02:34

0:00:18

0:00:18

0:00:30

0:00:30

0:00:27

0:00:27

0:05:28

0:05:28

0:02:44

0:02:44

0:00:07

0:00:07

0:00:14

0:00:14

0:00:40

0:00:40

0:01:00

0:01:00

0:05:35

0:05:35

0:00:49

0:00:49

0:09:59

0:09:59

0:16:21

0:16:21

0:03:20

0:03:20

0:00:27

0:00:27