filmov

tv

SMART SCM CONCEPT

Показать описание

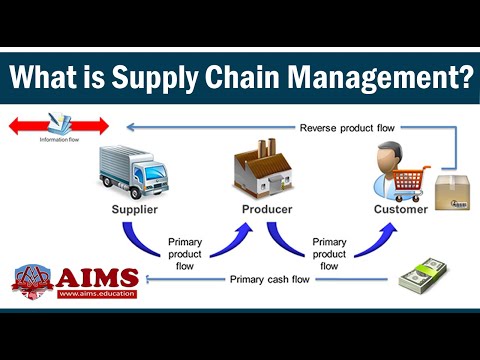

Market moves quickly, supply and demand is highly volatile and Our Supply chain is very complex.

We cannot predict things and if something can go wrong, it probably will.

Success or failure of our supply chain depends on how quickly and effectively stakeholders can identify, understand and respond to evolving situations.

In other words, we cannot be afford slow and inflexible.

A lot of existing process like BPR and supporting SAP tools are designed to help us a make better plan, but in unpredictable world how good can it really get, add to the fact that supply chain functions have been working in isolation.

Daily we all at SPRL are struggling the present processes are disconnected, difficult and slow that is where rapid response idea came with a modern solutions to managing our supply chain.

Rapid response breaks down the barriers to collaboration consensus and compromise by bringing our data analytics and we people together in one central system.

Which means you can do things differently.

Things were not able to do before with rapid response people across the organisation can plan better but as importantly when reality interrupts and it will, people can work together in unison across the supply chain to recognize problems analyse the impact of decisions and make immediate actions.

Driving significant business breakthroughs as a result

This is power of one solution.

In order to get rapid response, we decided and conceptualised, integrated, collaborative common platform tool to make smart and Lean supply chain management system.

Need of weekly demand forecasting identified to use for advanced planning for 12 weeks and 2 weeks advanced scheduling to ensure one time in full for every week.

We decided to upgrade present existing BPR to advanced BPR and proposing Demand forecasting to Long-range to short term demand sensing, advance Planning for MRP for 12 weeks, advanced BPR to convert demand into production plan and finally detailing advanced scheduling.

Detail RFP has been prepared by Cross function team and floated in market to get turkey solution from Global market leaders of SCM solutions. They also appreciated SPRL detail working approach and studied SPRL RFP to give best possible technical solution. Various software demo arranged by IT team, in which junior most to senior most stakeholders were actively participated including CPMS leadership team. Finally, all stakeholders convinced to go for integrated end to end Solutions. Finally presented proposal to MD & CEO on 17th June 2021 and received clearance to present in CMG.

In order to adhere all customers delivery promises, we must ensure On Time in Full every week, which we all know as OTIF.

We need to have a Smart Supply chain management system that not only takes care of not only meeting the customer demand, but also managing the raw material, tools, consumable and it integrates the best practices of the present BPR.

We are expecting minimum 20% reduction in working capital through inventory reduction and 1% reduction in change over losses, which will give minimum estimated saving for INR 3.5 Cr every year and additional other small benefits as well and team is working on this to prepare detail business case.

So let’s jump into the conceptual presentation and understand why the team concluded this, and what are the proposed ways to achieve this.

We cannot predict things and if something can go wrong, it probably will.

Success or failure of our supply chain depends on how quickly and effectively stakeholders can identify, understand and respond to evolving situations.

In other words, we cannot be afford slow and inflexible.

A lot of existing process like BPR and supporting SAP tools are designed to help us a make better plan, but in unpredictable world how good can it really get, add to the fact that supply chain functions have been working in isolation.

Daily we all at SPRL are struggling the present processes are disconnected, difficult and slow that is where rapid response idea came with a modern solutions to managing our supply chain.

Rapid response breaks down the barriers to collaboration consensus and compromise by bringing our data analytics and we people together in one central system.

Which means you can do things differently.

Things were not able to do before with rapid response people across the organisation can plan better but as importantly when reality interrupts and it will, people can work together in unison across the supply chain to recognize problems analyse the impact of decisions and make immediate actions.

Driving significant business breakthroughs as a result

This is power of one solution.

In order to get rapid response, we decided and conceptualised, integrated, collaborative common platform tool to make smart and Lean supply chain management system.

Need of weekly demand forecasting identified to use for advanced planning for 12 weeks and 2 weeks advanced scheduling to ensure one time in full for every week.

We decided to upgrade present existing BPR to advanced BPR and proposing Demand forecasting to Long-range to short term demand sensing, advance Planning for MRP for 12 weeks, advanced BPR to convert demand into production plan and finally detailing advanced scheduling.

Detail RFP has been prepared by Cross function team and floated in market to get turkey solution from Global market leaders of SCM solutions. They also appreciated SPRL detail working approach and studied SPRL RFP to give best possible technical solution. Various software demo arranged by IT team, in which junior most to senior most stakeholders were actively participated including CPMS leadership team. Finally, all stakeholders convinced to go for integrated end to end Solutions. Finally presented proposal to MD & CEO on 17th June 2021 and received clearance to present in CMG.

In order to adhere all customers delivery promises, we must ensure On Time in Full every week, which we all know as OTIF.

We need to have a Smart Supply chain management system that not only takes care of not only meeting the customer demand, but also managing the raw material, tools, consumable and it integrates the best practices of the present BPR.

We are expecting minimum 20% reduction in working capital through inventory reduction and 1% reduction in change over losses, which will give minimum estimated saving for INR 3.5 Cr every year and additional other small benefits as well and team is working on this to prepare detail business case.

So let’s jump into the conceptual presentation and understand why the team concluded this, and what are the proposed ways to achieve this.

0:04:32

0:04:32

0:03:28

0:03:28

0:06:36

0:06:36

0:01:32

0:01:32

0:04:58

0:04:58

0:03:24

0:03:24

0:03:11

0:03:11

0:05:08

0:05:08

0:06:27

0:06:27

0:07:10

0:07:10

0:03:06

0:03:06

0:04:17

0:04:17

0:02:41

0:02:41

0:12:08

0:12:08

0:07:33

0:07:33

0:04:22

0:04:22

0:03:05

0:03:05

0:03:09

0:03:09

0:01:47

0:01:47

0:01:51

0:01:51

0:26:32

0:26:32

0:05:43

0:05:43

0:01:18

0:01:18

0:04:37

0:04:37