filmov

tv

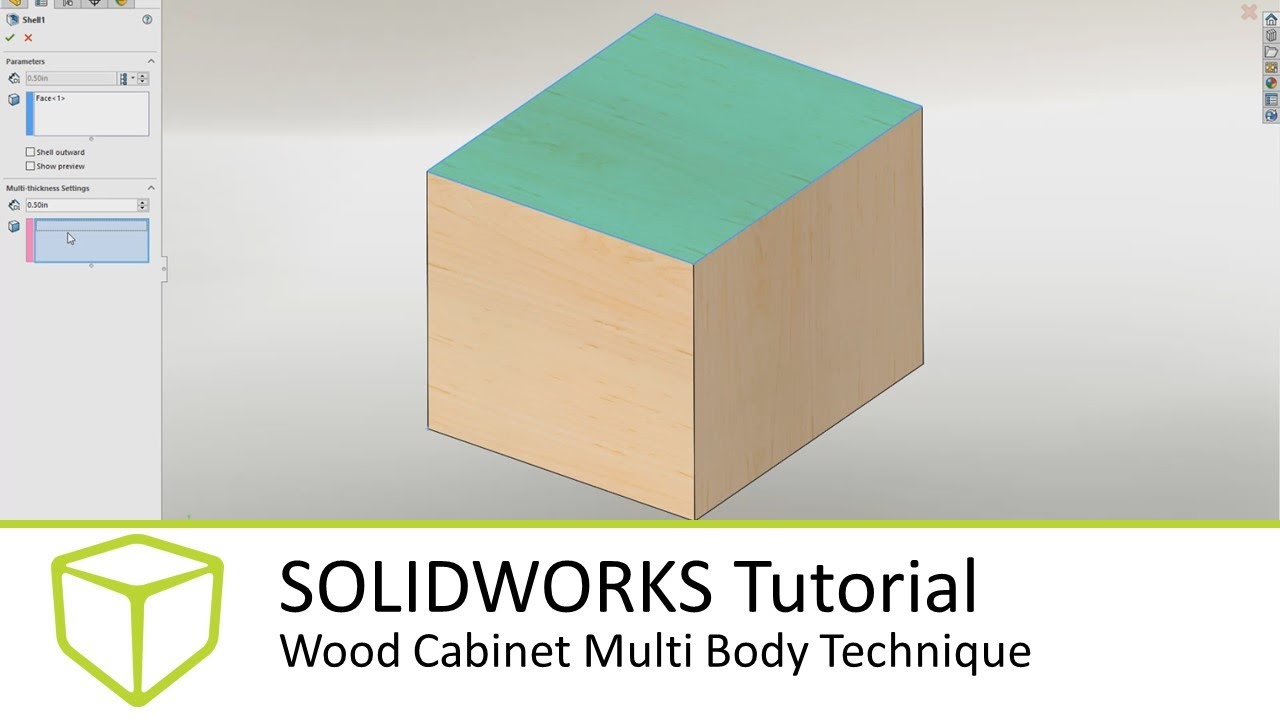

SOLIDWORKS Tutorial - Wood Cabinet Multi Body Technique

Показать описание

One of my favorite things to do is visit customers and see how they are doing things, and then try to streamline the steps they take in SOLIDWORKS to get that task done!

Working with SOLIDWORKS customers that often create boxs and cabinets made out of wood, I found the easiest way to create the necessary 3D geometry as well as get the Stock Size of each piece in just a few clicks.

Of course, if ANYTHING changes in the geometry, the Weldment Cut List will update to reflect the new dimensions.

This is a quick way to make any type of mulit panel construction using common and easy to use features in SOLIDWORKS.

@GOwithDarin

Also, follow us on Social media to get updates on what's new with all things SOLIDWORKS!!

SOLIDWORKS Tutorial - Wood Cabinet Multi Body Technique

SOLIDWORKS - DESIGN FURNITURE CABINET IN SOLIDWORKS

Cabinetry in SOLIDWORKS - Part 1

Introduction to SWOOD - Woodworking for SOLIDWORKS

Solidworks Tutorials | Furniture Design In Solidworks | Cabinetary Furniture

How to Build Furniture in SOLIDWORKS | Beginner SWOOD Tutorial

Introduction To Cabinetry Within SolidWorks Part 1: Multi-bodies

Solidworks Tutorials | Furniture Design In Solidworks | Cabinetary Furniture

Solidworks Tutorial | Desk Designs _ Design of a Simple Table-1 | 3d Modeling Tutorial

SolidWorks Tutorial: Using Design Tables to Create Cut Lists in BOM

Chair in Solidworks. Watch the full video tutorial on my YouTube channel. #solidworks #design

Wooden Case in Solidworks. Watch the full video tutorial on my YouTube channel. #solidworks #design

How to make wooden box in Solidworks

Solidworks 3D Modeling Simple Bookshelf Exercise 7

Wooden Table & Side Table #design #solidworks #glassfurniture # furniture

SolidWorks Tutorial | Furniture Designing

SolidWorks Tutorial Sheet Metal Cabinet tables open 2 floors1200x750x850mm

Solidworks exploded animation of a wood cabinet

Wooden Watchstand | SOLIDWORKS TUTORIAL

SOLIDWORKS for Cabinetry Design

Solid Wood Folding Multifunctional Dining Table for Small Apartments #3d #furniture #solidworks

Cabinet frame Solidworks

SOLIDWORKS for Furniture Design

Solidworks furniture and home design #3d #furniture #solidworks #design #cad3d #2d #table #cad

Комментарии

0:06:16

0:06:16

0:16:22

0:16:22

0:06:40

0:06:40

0:11:14

0:11:14

0:10:00

0:10:00

0:05:55

0:05:55

0:17:47

0:17:47

0:27:29

0:27:29

0:41:41

0:41:41

0:18:28

0:18:28

0:00:35

0:00:35

0:00:41

0:00:41

0:06:57

0:06:57

0:09:17

0:09:17

0:00:11

0:00:11

0:35:24

0:35:24

0:15:39

0:15:39

0:00:32

0:00:32

0:02:51

0:02:51

0:24:21

0:24:21

0:00:09

0:00:09

0:38:17

0:38:17

0:04:01

0:04:01

0:00:08

0:00:08