filmov

tv

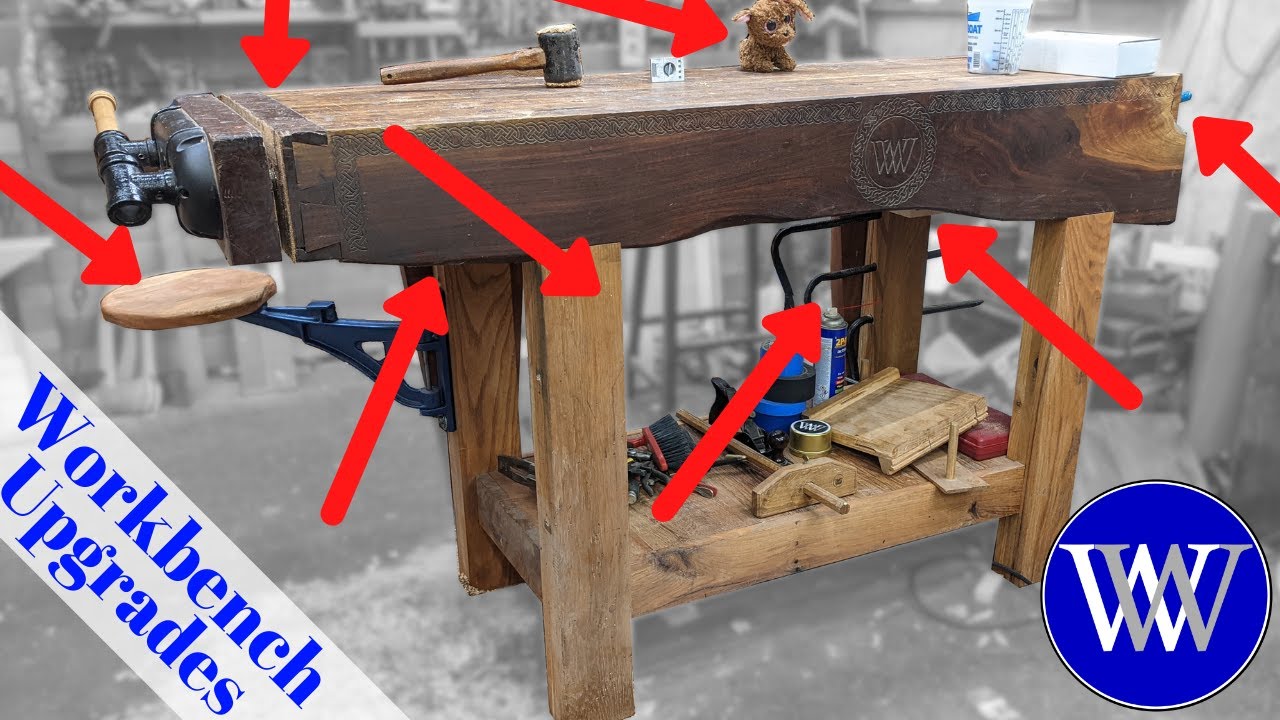

Bench Upgrades That I Love and Some I Don't

Показать описание

My workbench is the center of my woodworking shop. I have made many upgrades to my bench over the years. here are a few changes to my work bench that I love!

Join this channel to get access to perks:

---Tools I Suggest---

---Find Antique tools near you---

Top Patreon Supporters:

Blair Svihra Jr

Aaron Fenn

John Jugler

Andrew Wilson

Travis Reese

Tom West

Brandon Lauer

Brian Suker

Bruce Rose

////Help this channel grow\\\\

////You Can find me:\\\\

Instagram: @udostehle

Bench Upgrades That I Love and Some I Don't

DIY Fold Down Bench Seat ~ Backyard Upgrades #1

Review of the Bench Mate Upgrade from Masterpiece Models.

Workbench Upgrade With Hidden Bench Dogs

Upgrades to my Bench Crafted Moxon Vice

Stay safe this summer. Upgrade your bench with the Milescraft GrabberPRO. #woodworking

I LOVE this Incredible Home!

BENCH/ ACTIVE ALL ABOUT SHORTS (KIRK BONDAD)

L chesterfield Booth #furniture #sofa #bench #bespoke #upholstery #booth #design #chair #tabletop

Bench Grinder Upgrade

How To Get A Stronger Bench Press (3 Proven Methods You Need To Start Using)

Do you need ANY dogs on your bench? #shorts #woodwork

Upgrade Your Workbench with a Bench Vise

10 Home Bike Shop Upgrades that aren't Wrenches

182. Moxon Vise, the greatest bench appliance #mtbitesize #shorts #bench #appliance

Upgrade your self-care routine with this stunning Teakwood Shower Bench! 🪵✨

Transform Your Workshop with the Olsa Tools Steel-Forged Bench Vise @PureFunction #shorts

The best upgrade for your bench grinder!

MFT Work Bench Upgrade

Best Upgrade For Your Table Saw Miter Gauge | Rockler Skill Builders

Bench Upgrade | Fortnite Emote

Work Bench Upgrades (Continued)

How to Upgrade Crafting Bench to Rare in LEGO Fortnite

[Hardware] MK II Upgraded 15$ DIY Modular Test Bench Case

Комментарии

0:10:17

0:10:17

0:03:55

0:03:55

0:08:33

0:08:33

0:07:29

0:07:29

0:05:07

0:05:07

0:00:19

0:00:19

0:34:59

0:34:59

0:00:15

0:00:15

0:00:08

0:00:08

0:01:49

0:01:49

0:11:41

0:11:41

0:00:57

0:00:57

0:03:40

0:03:40

0:11:07

0:11:07

0:00:59

0:00:59

0:00:21

0:00:21

0:00:34

0:00:34

0:07:22

0:07:22

0:28:04

0:28:04

0:02:16

0:02:16

0:00:17

0:00:17

0:07:23

0:07:23

0:00:53

0:00:53

![[Hardware] MK II](https://i.ytimg.com/vi/Lo6zNPooNxU/hqdefault.jpg) 0:05:13

0:05:13