filmov

tv

Testing Our Greg Smith Equipment Atlas TC289 | Tool Tuesday

Показать описание

Hey, motorheads! In this video, Blair shows you how RevitAuto uses the Atlas TC289 Dual Arm Assist while doing a tire change and swapping in TPMS sensors from Autel. Blair goes over the specs and practical uses of this Atlas TC289.

Atlas TC289 Electric/Pneumatic Wheel Clamp Tire Changer with Bead Blaster

---

Product Description:

""

---

If you like this content, check out more videos in our playlists below! Be sure to check out our other playlists as well, including Ford F-Series repair videos and Fix It Friday!

---

#RevitAuto

---

RevitAuto Contact Info

(202) 827-5955

Atlas TC289 Electric/Pneumatic Wheel Clamp Tire Changer with Bead Blaster

---

Product Description:

""

---

If you like this content, check out more videos in our playlists below! Be sure to check out our other playlists as well, including Ford F-Series repair videos and Fix It Friday!

---

#RevitAuto

---

RevitAuto Contact Info

(202) 827-5955

Testing Our Greg Smith Equipment Atlas TC289 | Tool Tuesday

Greg Smith Equipment Atlas WB-41 Overview | Tool Tuesday

We Installed an Atlas 2 Post Car Lift from Greg Smith Equipment

Record BREAKING throw with STEPH CURRY at Crypto.com Arena!!

'Why I Fire People Every Day' - Warren Buffett

How Hard Candy Is Made | WIRED

Atlas Wheel Balancers from ASE Deals - Customer Submitted Video

We Got a 2 Post Lift!

Hailie Deegan upset with Lawless Alan after Martinsville Speedway #shorts

Top 10 SNL Impressions Done in Front of the Actual Person

TYRE MACHINE

Is the Atlas APEX 12 worth the savings?

Greg Smith Full Clean PR 185 Lb.

This is Why You Never Mess With a Royal Guard...

15,000 Lb Capacity 2 Post Truck Lift

Greg Smith

Peyton Manning can't believe this throw from Aaron Rodgers

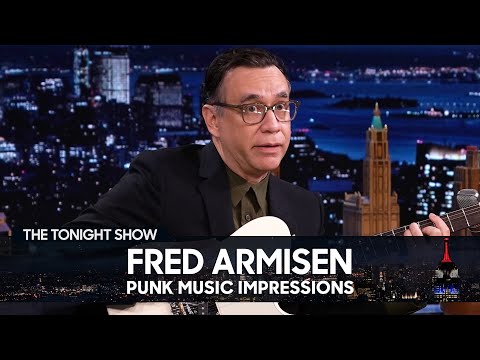

Fred Armisen Impersonates Each Decade of Punk Music | The Tonight Show Starring Jimmy Fallon

We Now Understand Why Frank Is No Longer On American Pickers

Black Widow BW-1000A Motorcycle lift

Heinz - SNL

Roy Orders 14 Free Samples of Ice Cream! | Extreme Cheapskates

Atlas Midrise Lift

Ryan Gosling Asks Stephen A Lord Of The Rings Question From His Mom

Комментарии

0:13:23

0:13:23

0:05:56

0:05:56

0:11:46

0:11:46

0:01:00

0:01:00

0:04:23

0:04:23

0:13:22

0:13:22

0:00:12

0:00:12

0:13:02

0:13:02

0:00:28

0:00:28

0:13:18

0:13:18

0:00:24

0:00:24

0:05:44

0:05:44

0:00:14

0:00:14

0:08:13

0:08:13

0:00:43

0:00:43

0:01:29

0:01:29

0:00:47

0:00:47

0:05:23

0:05:23

0:04:11

0:04:11

0:10:42

0:10:42

0:01:55

0:01:55

0:10:34

0:10:34

0:01:23

0:01:23

0:01:50

0:01:50