filmov

tv

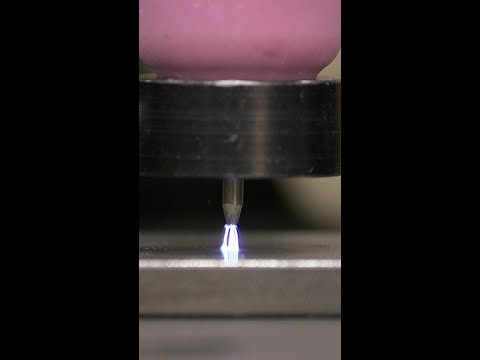

Welding, Tig welding 20, Tungsten inert gas, arc welding process (TIG) welding # shorts

Показать описание

Welding, Tig welding 20, Tungsten inert gas, arc welding process (TIG) welding # shorts

Gas tungsten arc welding (GTAW), also known as tungsten inert gas (TIG) welding, is an arc welding process that uses a non-consumable tungsten electrode to produce the weld. The weld area and electrode are protected from oxidation or other atmospheric contamination by an inert shielding gas (argon or helium).

▶ Welder's Handbook:

A Guide to Plasma Cutting, Oxyacetylene, ARC, MIG and TIG Welding, Revised and Updated

A newly-updated, state-of-the-art guide to MIG and TIG arc welding technology.

🔴 Check out this video too!

The best #Shorts!

A filler metal is normally used, though some welds, known as autogenous welds, or fusion welds do not require it. When helium is used, this is known as heliarc welding.

A constant-current welding power supply produces electrical energy, which is conducted across the arc through a column of highly ionized gas and metal vapors known as a plasma.

GTAW is most commonly used to weld thin sections of stainless steel and non-ferrous metals such as aluminum, magnesium, and copper alloys.

The process grants the operator greater control over the weld than competing processes such as shielded metal arc welding and gas metal arc welding, allowing for stronger, higher quality welds.

However, GTAW is comparatively more complex and difficult to master, and furthermore, it is significantly slower than most other welding techniques.

A related process, plasma arc welding, uses a slightly different welding torch to create a more focused welding arc and as a result is often automated.

Tig Welding,Cold Welding,MIG Welding,Welding

🔴 Please don't forget to subscribe to my channel!

Thank you 🙏

🔴 Check out this video too!

The best #Shorts!

Disclaimer: These videos are intended for entertainment purposes only and as such, you should not attempt to do any of the things you see me doing. Always read and follow the manufacturer’s safety guidelines before handling tools. Seek professional advice and training before using any tools or equipment. Never operate any tool without wearing the proper personal protective equipment.

Gas metal arc welding (GMAW), sometimes referred to by its subtypes metal inert gas (MIG) and metal active gas (MAG) is a welding process in which an electric arc forms between a consumable MIG wire electrode and the workpiece metal(s), which heats the workpiece metal(s), causing them to fuse (melt and join).

Along with the wire electrode, a shielding gas feeds through the welding gun, which shields the process from atmospheric contamination.

The process can be semi-automatic or automatic. A constant voltage, direct current power source is most commonly used with GMAW, but constant current systems, as well as alternating current, can be used.

There are four primary methods of metal transfer in GMAW, called globular, short-circuiting, spray, and pulsed-spray, each of which has distinct properties and corresponding advantages and limitations.

Originally developed in the 1940s for welding aluminium and other non-ferrous materials, GMAW was soon applied to steels because it provided faster welding time compared to other welding processes.

The cost of inert gas limited its use in steels until several years later, when the use of semi-inert gases such as carbon dioxide became common. Further developments during the 1950s and 1960s gave the process more versatility and as a result, it became a highly used industrial process.

Today, GMAW is the most common industrial welding process, preferred for its versatility, speed and the relative ease of adapting the process to robotic automation.

Unlike welding processes that do not employ a shielding gas, such as shielded metal arc welding, it is rarely used outdoors or in other areas of moving air.

A related process, flux cored arc welding, often does not use a shielding gas, but instead employs an electrode wire that is hollow and filled with flux.

🔴 Please don't forget to subscribe to my channel!

Thank you 🙏

🔴 Check out this video too!

The best #Shorts!

▶ Welder's Handbook:

A Guide to Plasma Cutting, Oxyacetylene, ARC, MIG and TIG Welding, Revised and Updated

A newly-updated, state-of-the-art guide to MIG and TIG arc welding technology.

Disclaimer: These videos are intended for entertainment purposes only and as such, you should not attempt to do any of the things you see me doing. Always read and follow the manufacturer’s safety guidelines before handling tools. Seek professional advice and training before using any tools or equipment. Never operate any tool without wearing the proper personal protective equipment.

Gas tungsten arc welding (GTAW), also known as tungsten inert gas (TIG) welding, is an arc welding process that uses a non-consumable tungsten electrode to produce the weld. The weld area and electrode are protected from oxidation or other atmospheric contamination by an inert shielding gas (argon or helium).

▶ Welder's Handbook:

A Guide to Plasma Cutting, Oxyacetylene, ARC, MIG and TIG Welding, Revised and Updated

A newly-updated, state-of-the-art guide to MIG and TIG arc welding technology.

🔴 Check out this video too!

The best #Shorts!

A filler metal is normally used, though some welds, known as autogenous welds, or fusion welds do not require it. When helium is used, this is known as heliarc welding.

A constant-current welding power supply produces electrical energy, which is conducted across the arc through a column of highly ionized gas and metal vapors known as a plasma.

GTAW is most commonly used to weld thin sections of stainless steel and non-ferrous metals such as aluminum, magnesium, and copper alloys.

The process grants the operator greater control over the weld than competing processes such as shielded metal arc welding and gas metal arc welding, allowing for stronger, higher quality welds.

However, GTAW is comparatively more complex and difficult to master, and furthermore, it is significantly slower than most other welding techniques.

A related process, plasma arc welding, uses a slightly different welding torch to create a more focused welding arc and as a result is often automated.

Tig Welding,Cold Welding,MIG Welding,Welding

🔴 Please don't forget to subscribe to my channel!

Thank you 🙏

🔴 Check out this video too!

The best #Shorts!

Disclaimer: These videos are intended for entertainment purposes only and as such, you should not attempt to do any of the things you see me doing. Always read and follow the manufacturer’s safety guidelines before handling tools. Seek professional advice and training before using any tools or equipment. Never operate any tool without wearing the proper personal protective equipment.

Gas metal arc welding (GMAW), sometimes referred to by its subtypes metal inert gas (MIG) and metal active gas (MAG) is a welding process in which an electric arc forms between a consumable MIG wire electrode and the workpiece metal(s), which heats the workpiece metal(s), causing them to fuse (melt and join).

Along with the wire electrode, a shielding gas feeds through the welding gun, which shields the process from atmospheric contamination.

The process can be semi-automatic or automatic. A constant voltage, direct current power source is most commonly used with GMAW, but constant current systems, as well as alternating current, can be used.

There are four primary methods of metal transfer in GMAW, called globular, short-circuiting, spray, and pulsed-spray, each of which has distinct properties and corresponding advantages and limitations.

Originally developed in the 1940s for welding aluminium and other non-ferrous materials, GMAW was soon applied to steels because it provided faster welding time compared to other welding processes.

The cost of inert gas limited its use in steels until several years later, when the use of semi-inert gases such as carbon dioxide became common. Further developments during the 1950s and 1960s gave the process more versatility and as a result, it became a highly used industrial process.

Today, GMAW is the most common industrial welding process, preferred for its versatility, speed and the relative ease of adapting the process to robotic automation.

Unlike welding processes that do not employ a shielding gas, such as shielded metal arc welding, it is rarely used outdoors or in other areas of moving air.

A related process, flux cored arc welding, often does not use a shielding gas, but instead employs an electrode wire that is hollow and filled with flux.

🔴 Please don't forget to subscribe to my channel!

Thank you 🙏

🔴 Check out this video too!

The best #Shorts!

▶ Welder's Handbook:

A Guide to Plasma Cutting, Oxyacetylene, ARC, MIG and TIG Welding, Revised and Updated

A newly-updated, state-of-the-art guide to MIG and TIG arc welding technology.

Disclaimer: These videos are intended for entertainment purposes only and as such, you should not attempt to do any of the things you see me doing. Always read and follow the manufacturer’s safety guidelines before handling tools. Seek professional advice and training before using any tools or equipment. Never operate any tool without wearing the proper personal protective equipment.

Комментарии

0:12:43

0:12:43

0:00:45

0:00:45

0:01:50

0:01:50

0:00:16

0:00:16

0:10:17

0:10:17

0:00:31

0:00:31

0:00:17

0:00:17

0:07:26

0:07:26

0:11:35

0:11:35

0:00:27

0:00:27

0:00:18

0:00:18

0:06:20

0:06:20

0:00:15

0:00:15

0:07:14

0:07:14

0:21:10

0:21:10

0:00:30

0:00:30

0:05:22

0:05:22

0:03:20

0:03:20

0:03:02

0:03:02

0:01:01

0:01:01

0:10:11

0:10:11

0:05:34

0:05:34

0:03:28

0:03:28

0:00:59

0:00:59