filmov

tv

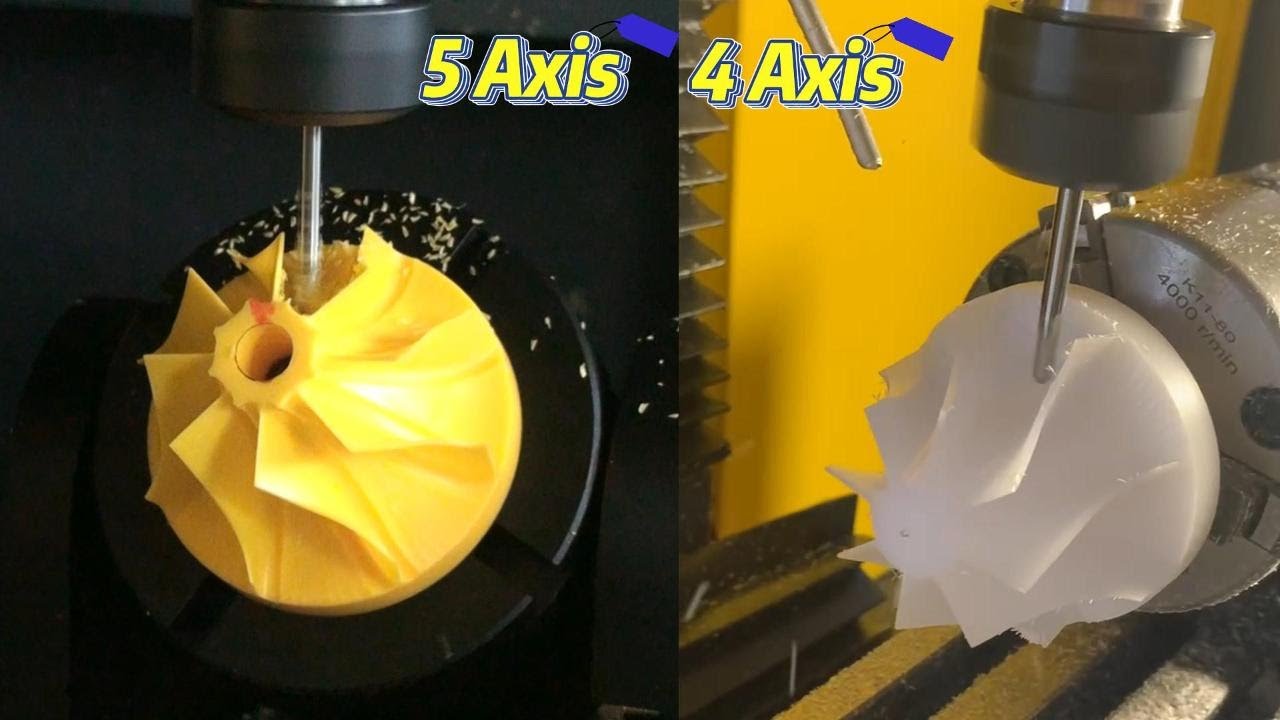

5/4 Axis Impeller machining by Yornew MX220 CNC Milling Machine.

Показать описание

- Are you looking for a reliable and versatile desktop 5-axis CNC milling machine?

- Do you want to see how the MX220 can handle complex and precise machining tasks with ease and efficiency?

- In this article, we will introduce the MX220 and show you how we tested its accuracy and performance by machining an impeller.

- An impeller is a rotating component that transfers energy from a motor to a fluid, such as water or air.

- Machining an impeller requires high precision and accuracy, as well as smooth surface finish and optimal geometry.

- The MX220 is a desktop 5-axis CNC milling machine that can handle such challenges with its powerful spindle, rigid structure, and advanced control system.

- The MX220 has a working area of 220 x 120 x 200 mm, and can accommodate workpieces up to 3 kg.

- The MX220 has a spindle speed of up to 24,000 rpm, and can use various tools with diameters ranging from 1 to 6 mm.

- The MX220 has a 5-axis simultaneous control system that allows for complex and dynamic movements of the spindle and the table.

- The MX220 has a user-friendly interface that supports G-code programming, as well as CAM software integration.

- To test the accuracy and performance of the MX220, we used a CAD model of an impeller and generated the toolpaths using Fusion 360 CAM software.

- We selected a suitable material (aluminum alloy) and tool (2 mm ball end mill) for the machining process.

- We set the machining parameters (feed rate, spindle speed, depth of cut, etc.) according to the recommended values for the material and tool.

- We mounted the workpiece on the table using a fixture and aligned it with the spindle using a probe.

- The impeller had a smooth surface finish and a high dimensional accuracy.

- The impeller also had a balanced geometry and a uniform distribution of blades.

- The MX220 demonstrated its ability to machine an impeller with high quality and efficiency, proving its suitability for various applications that require 5-axis CNC milling.

- Do you want to see how the MX220 can handle complex and precise machining tasks with ease and efficiency?

- In this article, we will introduce the MX220 and show you how we tested its accuracy and performance by machining an impeller.

- An impeller is a rotating component that transfers energy from a motor to a fluid, such as water or air.

- Machining an impeller requires high precision and accuracy, as well as smooth surface finish and optimal geometry.

- The MX220 is a desktop 5-axis CNC milling machine that can handle such challenges with its powerful spindle, rigid structure, and advanced control system.

- The MX220 has a working area of 220 x 120 x 200 mm, and can accommodate workpieces up to 3 kg.

- The MX220 has a spindle speed of up to 24,000 rpm, and can use various tools with diameters ranging from 1 to 6 mm.

- The MX220 has a 5-axis simultaneous control system that allows for complex and dynamic movements of the spindle and the table.

- The MX220 has a user-friendly interface that supports G-code programming, as well as CAM software integration.

- To test the accuracy and performance of the MX220, we used a CAD model of an impeller and generated the toolpaths using Fusion 360 CAM software.

- We selected a suitable material (aluminum alloy) and tool (2 mm ball end mill) for the machining process.

- We set the machining parameters (feed rate, spindle speed, depth of cut, etc.) according to the recommended values for the material and tool.

- We mounted the workpiece on the table using a fixture and aligned it with the spindle using a probe.

- The impeller had a smooth surface finish and a high dimensional accuracy.

- The impeller also had a balanced geometry and a uniform distribution of blades.

- The MX220 demonstrated its ability to machine an impeller with high quality and efficiency, proving its suitability for various applications that require 5-axis CNC milling.

0:00:44

0:00:44

0:00:46

0:00:46

0:03:38

0:03:38

0:01:00

0:01:00

0:02:17

0:02:17

0:00:12

0:00:12

0:00:16

0:00:16

0:01:41

0:01:41

0:00:09

0:00:09

0:00:08

0:00:08

0:00:12

0:00:12

0:02:33

0:02:33

0:00:31

0:00:31

0:17:07

0:17:07

0:10:13

0:10:13

0:31:33

0:31:33

0:04:16

0:04:16

0:00:12

0:00:12

0:00:15

0:00:15

0:00:33

0:00:33

0:00:16

0:00:16

0:01:13

0:01:13

0:03:00

0:03:00

0:00:18

0:00:18