filmov

tv

Getting Started with Predictive Maintenance

Показать описание

This video explains different maintenance strategies and walks you through a workflow for developing a predictive maintenance algorithm.

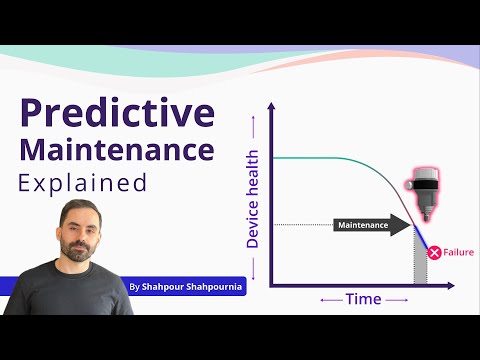

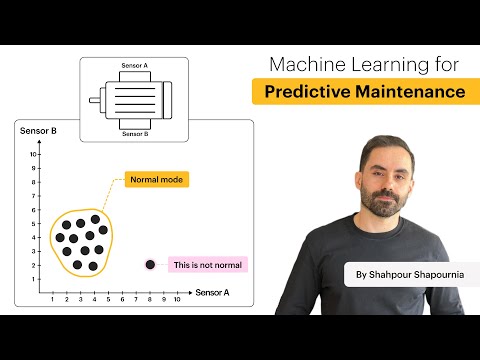

Predictive maintenance lets you find the optimum time to schedule maintenance by estimating time to failure. It also pinpoints problems in your machinery and helps you identify the parts that need to be fixed. Using predictive maintenance, you can minimize downtime and maximize equipment lifetime.

This video uses a triplex pump example to walk you through the predictive maintenance algorithm steps. To develop an algorithm, you need a large set of sensor data collected under different operating conditions. In cases, where sensor data is not enough, you can use simulation data that is representative of failures by creating a model of your machine and simulating faulty operating conditions. For more information on generating failure data using Simulink®, please check out the links given below.

© 2018 The MathWorks, Inc. MATLAB and Simulink are registered

trademarks of The MathWorks, Inc.

Predictive maintenance lets you find the optimum time to schedule maintenance by estimating time to failure. It also pinpoints problems in your machinery and helps you identify the parts that need to be fixed. Using predictive maintenance, you can minimize downtime and maximize equipment lifetime.

This video uses a triplex pump example to walk you through the predictive maintenance algorithm steps. To develop an algorithm, you need a large set of sensor data collected under different operating conditions. In cases, where sensor data is not enough, you can use simulation data that is representative of failures by creating a model of your machine and simulating faulty operating conditions. For more information on generating failure data using Simulink®, please check out the links given below.

© 2018 The MathWorks, Inc. MATLAB and Simulink are registered

trademarks of The MathWorks, Inc.

Getting Started with Predictive Maintenance

How to Get Started with Predictive Maintenance

Predictive Maintenance Explained

Getting Started With Machine Learning For Predictive Maintenance | Agosto CloudUp

How to Use Machine Learning for Predictive Maintenance

How to Get Started with Predictive Maintenance from Scratch

How to get started on an Electrical Predictive Maintenance Program (ePDM)

How to Use Machine Learning for Predictive Maintenance

Unlocking Predictive Maintenance: Save 30% on Costs

How Predictive Maintenance Saved $1 Million in Downtime! #ai #intelligentautomation #automation

AI and Predictive Maintenance 🛠️🤖 - AI FACTS

Predictive Maintenance with Machine Learning | Data Science & Engineering Recipes

Predictive Maintenance and More: How to Use Machine Learning Without Being a Data Scientist

AWS re:Invent 2020: Enable predictive maintenance for your industrial equipment

Predictive Maintenance: Unsupervised and Supervised Machine Learning

What is Predictive Maintenance?🧑🔧 👨🔧

Predictive Maintenance at the BMW iFACTORY

Vibration Analysis for beginners 2 (how to start your Predictive Maintenance)

Deep Dive: Machine Learning on the Edge - Predictive Maintenance

The 4 Steps to Getting Started with Your First Condition Monitoring (Predictive Maintenance) Project

Power of Predictive Maintenance with Data Science

Predictive Maintenance Explained #shorts #realpars

Cost Savings Through Predictive Maintenance

Predictive Maintenance Revolution 🛠️🚌

Комментарии

0:06:40

0:06:40

0:02:07

0:02:07

0:07:26

0:07:26

0:18:30

0:18:30

0:02:03

0:02:03

0:00:37

0:00:37

0:01:44

0:01:44

0:05:33

0:05:33

0:00:22

0:00:22

0:00:42

0:00:42

0:00:12

0:00:12

0:40:32

0:40:32

0:11:32

0:11:32

0:29:47

0:29:47

0:57:26

0:57:26

0:00:49

0:00:49

0:00:35

0:00:35

0:05:54

0:05:54

1:41:03

1:41:03

0:02:23

0:02:23

0:00:45

0:00:45

0:01:00

0:01:00

0:45:51

0:45:51

0:00:31

0:00:31