filmov

tv

Best Tool for Window Screen Replacement?

Показать описание

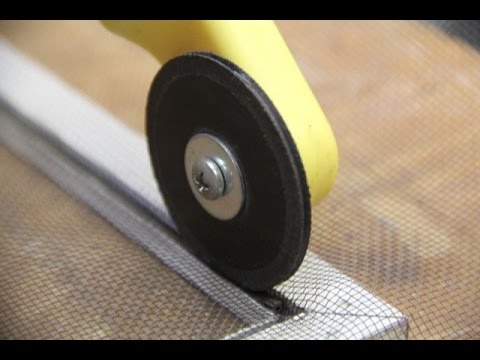

Testing and reviewing the Screen Mouse spline tool

Best Tool for Window Screen Replacement?

FLEXIBLE WINDOW SCREENS?? (SHARK TANK Thinks THIS is the FUTURE Of Window Screens...FLEXSCREEN!)

Screen Removal made EASY with This ONE Tool!

Window Screen Repair Tools - Spline Tool

Window Screen Repair Kit From Home Depot Is A Good Deal! #howto #tutorials #window #screen #repair

Build A Window Frame - Ace Hardware

See How the Right Screen Spline Tool Makes Screen Installations and Repairs Easy | Phifer Inc.

You can easily replace a window screen in 10 minutes using this repair kit!

window screen removing tool ebay. for window cleaners

How to Replace Your Ripped Window Screen Quick & Easy Tool Triz Screen

How To Replace Patio Screen

Screen Tool - Spline Rollers

Replace A Door Screen - Ace Hardware

TOP BEST 5 GLASS WINDOW CLEANING TOOLS GADGETS IN 2022

SCREEN CLEANER TIPS | WINDOW CLEANING TOOLS

Wrinkle-Free Window Screen Replacement | How to Tips | DIY Repair Replace Change Patch Fix Holes

Build-A-Screen Window Screen Kit

5 Free Screenshot Software You Must Try!

How to Replace a Damaged Window Screen - #diy #homeimprovement #windows #thriftdiving

How to rescreen a window screen in 3 minutes

Window Screen Spline Roller Tool

How to Rescreen a Window Screen

Installing Outdoor Screens the Right Way.

Replacing a Window Screen 5-Steps

Комментарии

0:05:28

0:05:28

0:08:43

0:08:43

0:03:55

0:03:55

0:00:41

0:00:41

0:01:12

0:01:12

0:07:58

0:07:58

0:01:24

0:01:24

0:00:53

0:00:53

0:00:16

0:00:16

0:07:03

0:07:03

0:04:55

0:04:55

0:00:56

0:00:56

0:07:47

0:07:47

0:04:26

0:04:26

0:05:21

0:05:21

0:11:43

0:11:43

0:00:34

0:00:34

0:05:52

0:05:52

0:00:49

0:00:49

0:03:47

0:03:47

0:00:14

0:00:14

0:00:59

0:00:59

0:00:47

0:00:47

0:04:10

0:04:10