filmov

tv

EEVblog #155 - ITead Studio PCB Prototype Goof

Показать описание

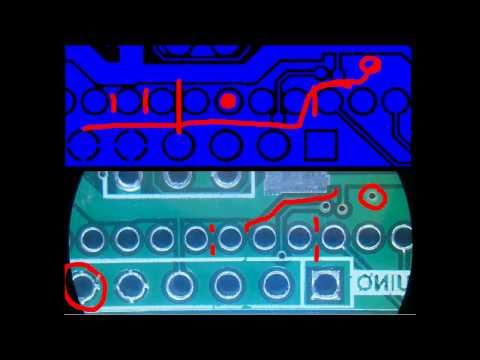

Dave shares an experience with his new prototype PCB's from ITead Studio.

Super awesomely cheap, but beware!

Super awesomely cheap, but beware!

EEVblog #155 - ITead Studio PCB Prototype Goof

EEVblog #138 - Top 5 Tips for Graduate Engineers

EEVblog #161 - 555 April Fools Revealed

EEVblog#160 - 555 Timer Easter Egg?

EEVblog #146 - Digikey Postage FAIL

EEVblog #135 - Kindle Case Mythbusting

EEVblog #134 - The Maxim Manipulation

EEVblog #132 - Delusional Dyson Marketing

EEVblog #191 - Mouse Trap Triggering

EEVblog #101 - Hacking your own Peltier LAB Thermal Chamber

EEVblog #190 - Live Show #9

Mitsubishi iMiEV Electric Car Test Drive - EEVblog #179

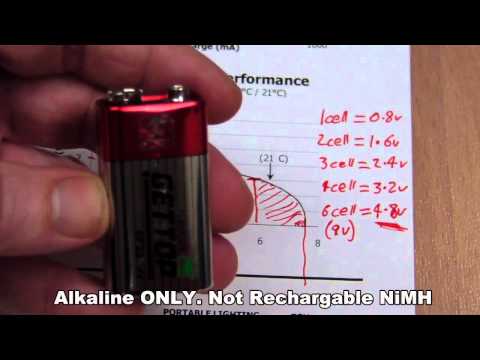

EEVblog #140 - Battery Capacity Tutorial

EEVblog #133 - Dodgy Digikey Components

EEVBlog #543 - PCB VIA Current Investigation

EEVblog #55 - RCA Airnergy WiFi Charging Free Energy Harvesting Marketing BS

EEVblog #124 - A Tour of Apex Electronics

eevBLAB #21 - Star Wars VII The Force Awakens Review

EEVblog #130 - The µCalc Credit Card Scientific Calculator / Computer

EEVblog #181 - Dead Bug Prototype Soldering

EEVblog #149 - Agilent Infiniivision 3000 X Series Oscilloscope Review

Unboxing the Texting Dryer PCB

KiCAD Basics - Part 3 - Gerber Export & OSHPark Ordering

The secret life of a lawyer

Комментарии

0:11:45

0:11:45

0:03:08

0:03:08

0:13:25

0:13:25

0:03:19

0:03:19

0:15:35

0:15:35

0:15:29

0:15:29

0:02:53

0:02:53

0:14:04

0:14:04

0:22:39

0:22:39

1:51:43

1:51:43

0:27:17

0:27:17

0:29:01

0:29:01

0:17:40

0:17:40

0:27:45

0:27:45

0:11:13

0:11:13

0:15:19

0:15:19

0:11:31

0:11:31

0:20:51

0:20:51

0:11:31

0:11:31

0:25:30

0:25:30

0:07:38

0:07:38

0:08:31

0:08:31

0:10:51

0:10:51