filmov

tv

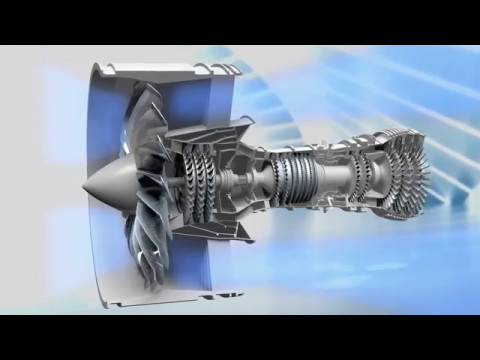

Compressors - Turbine Engines: A Closer Look

Показать описание

Lets look around inside the compressors of a few different turbine engines. How does it all fit together, where does the air go, and how does it work ?

Compressors - Turbine Engines: A Closer Look

Compressors Part 1 - Aircraft Gas Turbine Engines #05

How Jet Engines Work

How Jet Engines Work

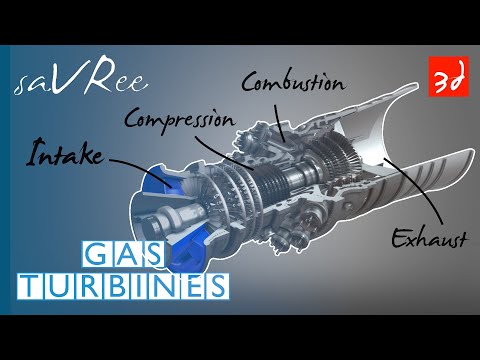

How Gas Turbines Work (Combustion Turbine Working Principle)

Mentour Pilot - Compressor Stall / Engine Surge Animation

How a Gas Turbine Works

Jet Engine, How it works?

Gas Turbine Compressors Explained | Advanced Axial Compressor Design & Thermodynamics #technolog...

The Diffuser - Turbine Engines: A Closer Look

How Jet Engines Work — Cirrus Vision Jet Engine | Williams International FJ33-5A Fanjet Engine

How Jet Engines Work

How does gas turbine engine: compressor section work?

Stators, Combustors and Turbines - Turbine Engines: A Closer Look

THREE TYPES OF COMPRESSORS ON JET ENGINES

How Rainwater Boosts Jet Engine Thrust

compressor blades, gas turbines, gas turbine turning tools #SHORTS

Why Jet Engines have a Speed Limit

Understanding Helicopter's Engine | Turboshaft

LOW vs. HIGH PRESSURE COMPRESSOR and SINGLE SPOOL vs MULTI-SPOOL ENGINES

Compressor section of a J34 Turbine Engine! This is why you don't wanna get sucked into an engi...

Free Turbine Turboprop Engine Cheat Sheet | Pilot Tutorial

Free Turbine Turboprop Engine

Jet Engine Evolution - From Turbojets to Turbofans

Комментарии

0:07:48

0:07:48

0:12:48

0:12:48

0:05:01

0:05:01

0:03:13

0:03:13

0:16:09

0:16:09

0:00:34

0:00:34

0:01:16

0:01:16

0:05:21

0:05:21

0:07:53

0:07:53

0:06:32

0:06:32

0:08:26

0:08:26

0:00:55

0:00:55

0:21:58

0:21:58

0:02:39

0:02:39

0:07:37

0:07:37

0:00:27

0:00:27

0:00:11

0:00:11

0:01:00

0:01:00

0:05:37

0:05:37

0:16:28

0:16:28

0:00:09

0:00:09

0:00:31

0:00:31

0:00:31

0:00:31

0:13:23

0:13:23