filmov

tv

What is the Best HMI Panel? | How to Choose the Best HMI Panel for Your Application

Показать описание

=============================

▶ Check out the full blog post over at

=============================

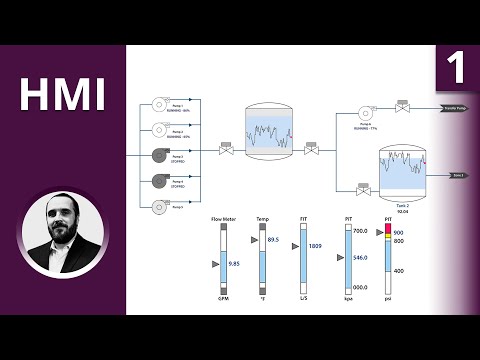

HMI Panels are valuable tools that are used by operators and engineers worldwide to visualize and monitor the process, provide control targets and set-points, execute programs and initiate sequences, and troubleshoot problems via trends, alarms, and events.

In this video, you will learn:

– What common features to consider when choosing an HMI

– What the differences are in a variety of HMI Panels offered by top manufacturers?

– How to determine which HMI Panel is the best for my application

HMI is short for Human Machine Interface. Just as the acronym implies, these panels provide a visual interface between the machines, equipment and process, and the operator or engineer.

Most plants use multiple HMI panels in locations that are convenient for the operator, and each is configured to provide the data that the operator needs at that location.

I want to select an HMI panel that is right for my application. How do I choose the best HMI panel?

1) Display size

The first consideration is the display size.

HMI panels come in all sizes, typically from 3 inches to 25 inches.

2) Touchscreen?

Touchscreens are convenient and allow a fast response, but they are more expensive than models with only function and arrow keys.

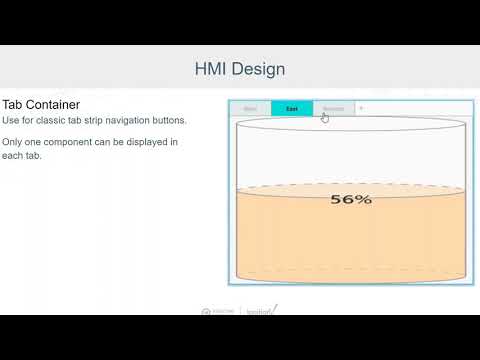

3) Color or Monochrome?

Color HMI panels are vivid and allow for status to easily be shown with colors, but monochrome units are less costly and very efficient for showing a small amount of data, like speed feedback or time left in a batch.

4) Resolution

What screen resolution is required to show sufficient graphic object details or allow display of many objects on the same screen?

5) Mounting

What about mounting? Should the HMI be flush mounted in a panel? Or on a pedestal? Or be Handheld?

6) Protections

What kind of protection does the HMI require? IP67 to protect against splashing of liquids or outdoor installation?

7) Interfaces

What interfaces do I require? Ethernet? Profinet? Serial interfaces for laboratory instruments, RFI scanners, or barcode readers? And do I require multiple interface types?

8) Software requirement

What are my software requirements? Do I need OPC or a specialized driver to access data from my controllers?

10) Supports Windows?

Does the HMI need to support Windows and its file system, or will the vendor’s HMI application be sufficient?

Let’s look at HMI panels for several different scenarios.

Example 1) Let’s say I need an HMI panel that has at least a 12” touchscreen.

I need network security built into the panel and have automatic program backup.

The MTP 1200 is the perfect HMI panel for this application.

Example 2) If my needs are more basic and my budget is tight the KTP 1200 Basic HMI Panel is just what I need.

The KTP basic panels are value-priced but are still rugged and have great performance characteristics.

Example 3) Suppose I have an HMI in a tank farm, and I want an HMI panel that can communicate with my controller wirelessly.

Maple Systems HMI 5103L has a 10-inch touchscreen, a bright LCD display, and can operate on 24 volts DC. This is the perfect HMI for monitoring tank levels and other tank farm sensors and equipment in the field.

Example 4) What if I need to connect my HMI to an Ethernet/IP network, as I would for a Rockwell Automation PLC, and connect a device like a barcode reader for a weigh and dispense system?

The answer may be to choose a PanelView Plus 7 standard model with a 9-inch display to monitor the weighing process.

If I have the same need but need a fully compliant panel for use in a cleanroom environment, like for a pharmaceutical plant, I can choose the PanelView Plus 7 stainless steel performance model.

And if I need to operate in a hazardous environment, the ArmorView Plus7 model is a perfect choice.

=============================

Missed our most recent videos? Watch them here:

=============================

To stay up to date with our last videos and more lessons, make sure to subscribe to this YouTube channel:

=============================

=============================

#HMI #RealPars #Industry

Комментарии

0:07:25

0:07:25

0:04:01

0:04:01

0:02:27

0:02:27

0:09:38

0:09:38

0:01:03

0:01:03

0:04:24

0:04:24

0:14:14

0:14:14

0:07:36

0:07:36

0:00:49

0:00:49

0:03:36

0:03:36

0:05:44

0:05:44

0:00:54

0:00:54

0:00:19

0:00:19

0:06:27

0:06:27

0:01:12

0:01:12

0:00:15

0:00:15

0:00:32

0:00:32

0:00:16

0:00:16

0:03:31

0:03:31

0:00:21

0:00:21

0:04:57

0:04:57

0:00:32

0:00:32

0:01:40

0:01:40

0:01:39

0:01:39