filmov

tv

Valve Float! What Is It, And How To Avoid It | Engine Masters | MotorTrend

Показать описание

We all know valve float as the evil that lurks beyond the redline, the dreaded robber of horsepower and destroyer of valves. But what is it really? What does it look like when it happens? And how can you put it as high in the RPM band as possible?

#motortrend #engine #enginemasters

MotorTrend is the ultimate streaming destination for gearheads coupled with the latest automotive research and news.

Start your MotorTrend Streaming Free Trial today!

Follow MotorTrend for the latest!

#motortrend #engine #enginemasters

MotorTrend is the ultimate streaming destination for gearheads coupled with the latest automotive research and news.

Start your MotorTrend Streaming Free Trial today!

Follow MotorTrend for the latest!

Valve Float! What Is It, And How To Avoid It | Engine Masters | MotorTrend

Valve Float ** What It Looks Like

A little valve float action on the dyno.

Astra VXR **what valve float sounds like**

Valve float

Jason Valve Float

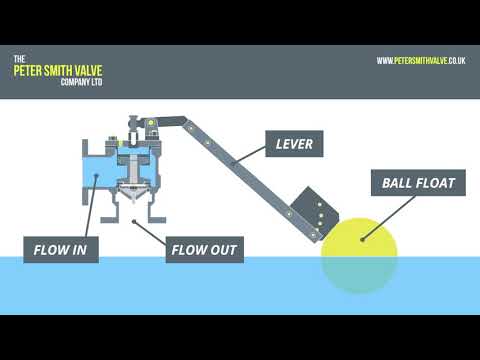

Peter Smith Valves - How a Float Valve Operates

Turbo Miata Valve Float. Head and Block Destroyed

MG Midget 1275 twin SU Carburettor & Maniflow rebuild PART 1 - The Birth of a Racecar (Episode 3...

Float Valve Problems

Valve float in the beater

360 SBC Tunnel Ram Dyno - valve float

How Float Valves Work

Floating Valve Mechanism And How it's Work in 3D Animation|how float value work

HOW TO CURE VALVE FLOAT & ADD 40-50 HP WITH A VALVE SPRING UPGRADE. AIR FLOW VS VALVE CONTROL!

What is valve float Dad?

FlexPVC - All About Float Valves. Different sizes and applications

Instant Pot Float Valve Tip

88cc chinese engine valve float at school

Which Automatic Water Level Control Float Valve should I use for my water tank?

Watts Heavy Duty Mechanical Float Valves

A10B Bi-Level Float Control Valve

Float Valve | Overhead tank float valve | #plumbing #mep #phe #tank #floatvalve #float #water #alam

XR6 Turbo potential valve float

Комментарии

0:10:56

0:10:56

0:01:19

0:01:19

0:00:24

0:00:24

0:00:43

0:00:43

0:01:00

0:01:00

0:00:23

0:00:23

0:00:34

0:00:34

0:00:22

0:00:22

0:10:31

0:10:31

0:01:08

0:01:08

0:00:19

0:00:19

0:00:36

0:00:36

0:05:34

0:05:34

0:02:20

0:02:20

0:12:03

0:12:03

0:00:46

0:00:46

0:05:35

0:05:35

0:00:23

0:00:23

0:01:27

0:01:27

0:04:09

0:04:09

0:00:57

0:00:57

0:00:23

0:00:23

0:00:16

0:00:16

0:00:48

0:00:48