filmov

tv

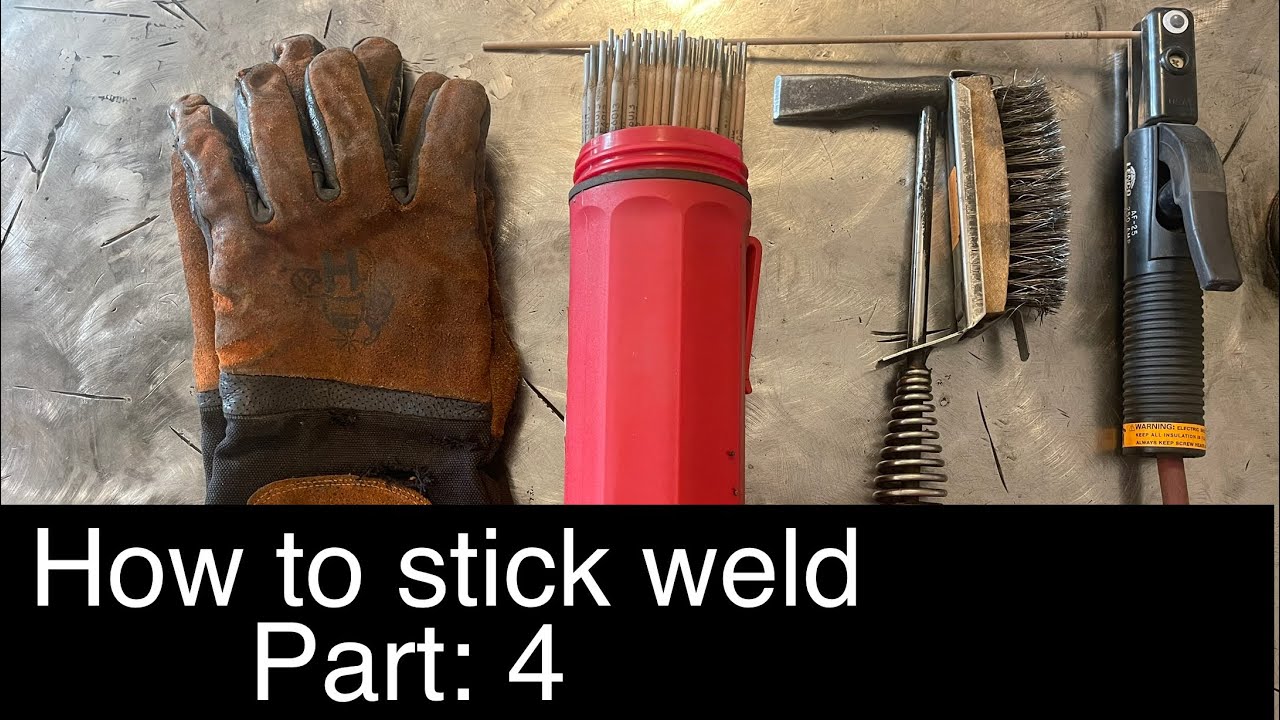

How to stick weld 👨🏻🏭: How to weld Butt joints (Series part 4)

Показать описание

On episode 4 we tackle butt joints and fix common welding mistakes

STICK WELDING 101: Getting Started With SMAW

Stick Welding: #1 Beginner Mistake and How to Fix It

Stick WELDING for Beginners: How to Stick Weld 101

Stick Welding Basics for Beginners: How to Stick Weld

Stick Welding Basics: Practice Drills

Stick Welding Basics: Full Tutorial

secret trick stick welding , why no welders talk about this

What is STICK Welding? (SMAW)

How to Strike an Arc: Stick Welding Basics for Beginners

How to stick weld 👨🏻🏭: Intro to Arc welding for beginners, (Series Part 1)

How to Stick Weld with 6013 Electrodes

Stick Welding Basics - How to Run Straight Consistent Beads

quick tricks to learn welding better and easier

3 Beginner tips for stick welding

How To Arc (Stick) Weld

novice welder may not know the best way to weld a thin square tube #howtoweldingforbeginners

Stick WELDING Basics: How to ARC Weld 101

9 Stick Welding Tips and Tricks!! (Improve your Stick welding today)

Stick Welding: How to Read the Puddle

How to stick weld 👨🏻🏭: Intro to Arc welding for beginners (Series Part 1.5)

stop bad welding !!! three welding techniques position 2f

Stick Welding Basics: How to Have Great Technique

Do this instead (3 Stick Welding Tips)

6013 Stick Welding Problem Fixed

Комментарии

0:23:47

0:23:47

0:06:06

0:06:06

0:07:34

0:07:34

0:24:09

0:24:09

0:13:34

0:13:34

0:14:38

0:14:38

0:00:31

0:00:31

0:04:20

0:04:20

0:06:06

0:06:06

0:30:17

0:30:17

0:07:44

0:07:44

0:13:50

0:13:50

0:00:43

0:00:43

0:00:56

0:00:56

0:02:53

0:02:53

0:01:00

0:01:00

0:08:58

0:08:58

0:05:10

0:05:10

0:06:06

0:06:06

0:38:17

0:38:17

0:03:50

0:03:50

0:08:31

0:08:31

0:13:33

0:13:33

0:05:34

0:05:34