filmov

tv

4 Tips to Eliminate ALL Snipe in Thickness Planers and

Показать описание

In this video I show you how to eliminate snipe when using a thickness planer. I also show how to properly set up the infeed and outfeed tables. The Thickness Planer I use is a DeWalt DW734, but this information applies to all similarly operating planers. You can find an approximate transcript of the video below.

Here are some Amazon affiliate links where I get a small percentage if you use them to purchase a product:

DeWalt DW734 Thickness Planer

Metal Straight Edge for calibrating your planer:

Approximate Transcript:

So, I’ve had some viewers leave comments asking how to reduce snipe on a wood planer such as this DeWalt one I have.

There’s one thing that will clear up about 95% of it. And I’ll show you how to do it along with some other tips.

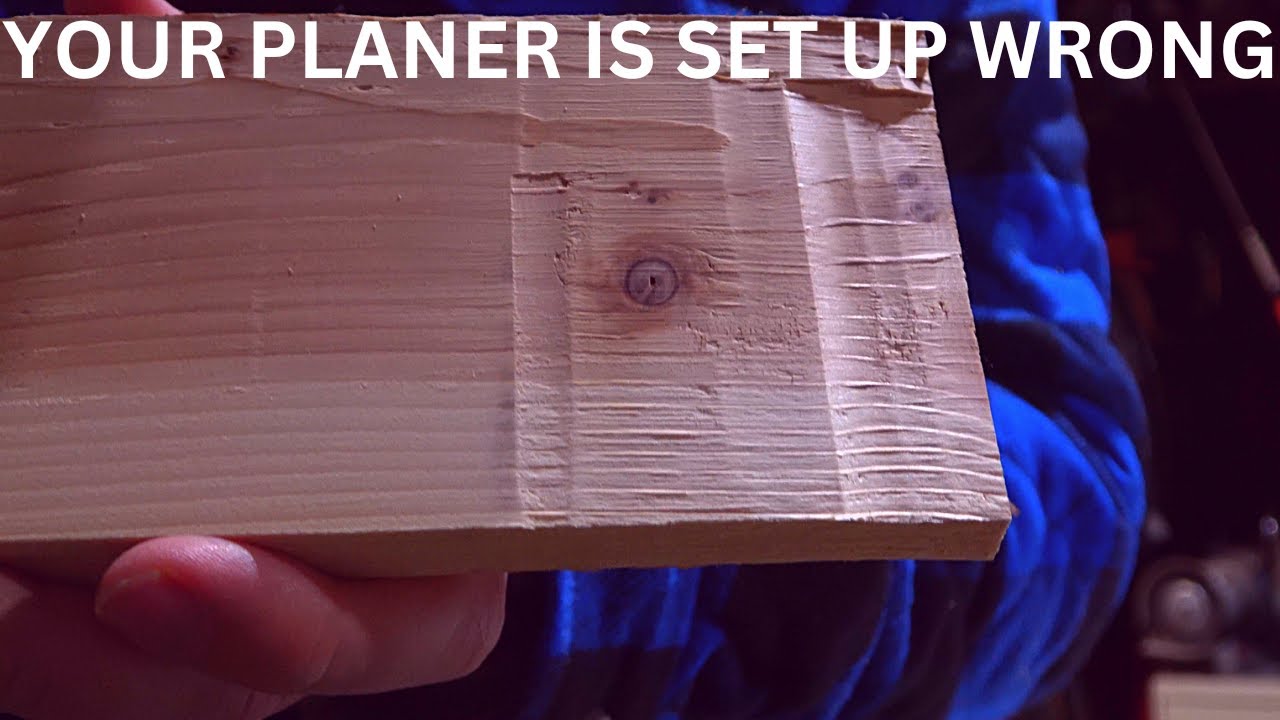

First, snipe is a deeper cut on either the leading or following end of a board, usually caused by improper setup or use of a wood planer or jointer.

Often time people get these larger power tools and assume they’re calibrated and ready to go from the factory. In my experience, that just isn’t the case. Everything from a table saw to a jointer, to a planer and in between will need to be checked to make sure it’s properly set up.

The average person’s planer has a couple infeed and outfeed tables that may fold up and down and a bed in the middle. The most important part of initial calibration is to make sure that the end if the infeed and outfeed tables are perfectly in line with the plane of the bed.

The way you do this is first get a straight edge, like this long metal ruler I have. Always check your reference edge with another one (Such as this level) to make sure it is actually straight.

Then you will want to put the edge on the bed and across the ends of the infeed and outfeed tables. You will also want a flashlight to help you see whether there are air gaps. If there are gaps either raise or lower the respective bolts to remove it. You may have to do this several times until you figure out the right balance between both sides to get everything just right.

Remember that woodworking is an exercise in patience, and the more patient and exact you are when calibrating your tools, the less issues you’ll have at every other step down the line.

Keep the wood even with the plane of the bed. You don’t want either end to dip or raise when entering or exiting the planer.

Also, remember not to cut too much at once. Remember, you can’t be in a hurry, and get great results.

As an Amazon Associate I earn from qualifying purchases.

For business inquiries:

P.O. Box 271

Oxford, IN 47971

Here are some Amazon affiliate links where I get a small percentage if you use them to purchase a product:

DeWalt DW734 Thickness Planer

Metal Straight Edge for calibrating your planer:

Approximate Transcript:

So, I’ve had some viewers leave comments asking how to reduce snipe on a wood planer such as this DeWalt one I have.

There’s one thing that will clear up about 95% of it. And I’ll show you how to do it along with some other tips.

First, snipe is a deeper cut on either the leading or following end of a board, usually caused by improper setup or use of a wood planer or jointer.

Often time people get these larger power tools and assume they’re calibrated and ready to go from the factory. In my experience, that just isn’t the case. Everything from a table saw to a jointer, to a planer and in between will need to be checked to make sure it’s properly set up.

The average person’s planer has a couple infeed and outfeed tables that may fold up and down and a bed in the middle. The most important part of initial calibration is to make sure that the end if the infeed and outfeed tables are perfectly in line with the plane of the bed.

The way you do this is first get a straight edge, like this long metal ruler I have. Always check your reference edge with another one (Such as this level) to make sure it is actually straight.

Then you will want to put the edge on the bed and across the ends of the infeed and outfeed tables. You will also want a flashlight to help you see whether there are air gaps. If there are gaps either raise or lower the respective bolts to remove it. You may have to do this several times until you figure out the right balance between both sides to get everything just right.

Remember that woodworking is an exercise in patience, and the more patient and exact you are when calibrating your tools, the less issues you’ll have at every other step down the line.

Keep the wood even with the plane of the bed. You don’t want either end to dip or raise when entering or exiting the planer.

Also, remember not to cut too much at once. Remember, you can’t be in a hurry, and get great results.

As an Amazon Associate I earn from qualifying purchases.

For business inquiries:

P.O. Box 271

Oxford, IN 47971

Комментарии

0:07:55

0:07:55

0:00:30

0:00:30

0:00:26

0:00:26

0:00:13

0:00:13

0:00:39

0:00:39

0:00:59

0:00:59

0:00:30

0:00:30

0:00:31

0:00:31

0:11:40

0:11:40

0:04:47

0:04:47

0:00:38

0:00:38

0:00:29

0:00:29

0:18:14

0:18:14

0:00:50

0:00:50

0:00:52

0:00:52

0:00:49

0:00:49

0:00:45

0:00:45

0:01:00

0:01:00

0:00:15

0:00:15

0:00:27

0:00:27

0:00:58

0:00:58

0:05:46

0:05:46

0:00:29

0:00:29

0:00:45

0:00:45