filmov

tv

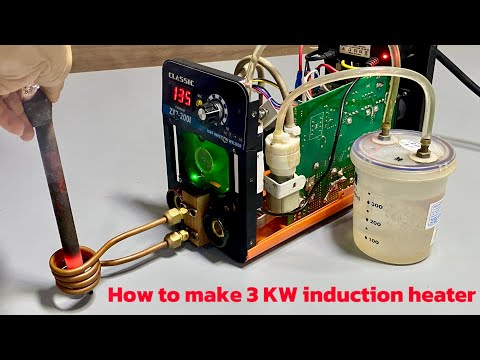

Induction forge

Показать описание

An induction forge has been something I have been interested in for quite some time. I finally had the chance to pick one up. Here is my first look at what it may be capable of.

My name is John Switzer, I operate Black Bear Forge, a small one person blacksmith shop located in southern Colorado. My current focus is shifting away from commissions and customer orders and towards education through these videos on YouTube. Thank you for watching

To provide financial support use one of the two links below.

Or you may set up a monthly contribution through Patreon

Mailing address:

Black Bear Forge

P.O. Box 4

Beulah, CO 81023

If you are curious about some of my other interests, you may like my second channel

John Switzer

Find me online at:

Below you will find useful links that will help you in your journey as a blacksmith.

My blacksmiths apron

RZmask 99.5% dust mask

To find more information in blacksmithing in the US or to search for your local ABANA affiliate group visit.

Blacksmithing tools and supplies

Most of my videos are shot on the Canon M50

Audio is recorded using the RodeLink Filmmaker Wireless Microphone Kit

Blacksmithing and related activities can be hazardous. These videos are not a substitute for competent professional instruction. Your safety is your sole responsibility. Always use appropriate safety equipment including eye and ear protection when working in the shop. Follow manufactures safety guidelines for the use of all equipment. In the event something shown in one of these videos seems unsafe, it is up to you to make the appropriate changes to protect yourself.

My name is John Switzer, I operate Black Bear Forge, a small one person blacksmith shop located in southern Colorado. My current focus is shifting away from commissions and customer orders and towards education through these videos on YouTube. Thank you for watching

To provide financial support use one of the two links below.

Or you may set up a monthly contribution through Patreon

Mailing address:

Black Bear Forge

P.O. Box 4

Beulah, CO 81023

If you are curious about some of my other interests, you may like my second channel

John Switzer

Find me online at:

Below you will find useful links that will help you in your journey as a blacksmith.

My blacksmiths apron

RZmask 99.5% dust mask

To find more information in blacksmithing in the US or to search for your local ABANA affiliate group visit.

Blacksmithing tools and supplies

Most of my videos are shot on the Canon M50

Audio is recorded using the RodeLink Filmmaker Wireless Microphone Kit

Blacksmithing and related activities can be hazardous. These videos are not a substitute for competent professional instruction. Your safety is your sole responsibility. Always use appropriate safety equipment including eye and ear protection when working in the shop. Follow manufactures safety guidelines for the use of all equipment. In the event something shown in one of these videos seems unsafe, it is up to you to make the appropriate changes to protect yourself.

Комментарии

0:17:28

0:17:28

0:01:00

0:01:00

0:31:37

0:31:37

0:00:52

0:00:52

0:00:24

0:00:24

0:16:00

0:16:00

0:00:14

0:00:14

0:17:11

0:17:11

0:13:37

0:13:37

0:00:36

0:00:36

0:07:28

0:07:28

0:12:26

0:12:26

0:00:10

0:00:10

0:00:25

0:00:25

0:00:16

0:00:16

0:01:01

0:01:01

0:00:16

0:00:16

0:00:36

0:00:36

0:09:38

0:09:38

0:00:49

0:00:49

0:00:16

0:00:16

0:00:59

0:00:59

0:18:28

0:18:28

0:00:49

0:00:49