filmov

tv

Bluing Steel Parts Tutorial

Показать описание

We're bluing some of the steel parts on Copperhead and decided to show how easy the process is.

00:00 Intro

00:27 Requirements

01:38 Part Preparation

02:43 Cleaning the Parts

03:20 Applying the Solution

04:27 Rinsing the Parts

04:53 Drying the Parts

05:04 Oiling the Parts

05:45 Finished Parts!

00:00 Intro

00:27 Requirements

01:38 Part Preparation

02:43 Cleaning the Parts

03:20 Applying the Solution

04:27 Rinsing the Parts

04:53 Drying the Parts

05:04 Oiling the Parts

05:45 Finished Parts!

Bluing Steel Parts Tutorial

Cold Bluing Steel Parts - Quick & Easy!

Cold bluing process

How To Blue a Gun using Birchwood Casey's Perma Blue Liquid Gun Blue Kit

Best Way To Blue Steel? Cold Blue, Hot Blue or Rust Bluing.

How to Turn Steel Black - All you need to know about Bluing

DIY 'hot blued' steel parts

Cold Bluing Steel Parts At Home Under 2 Minutes - Part 1

Turn Steel Black - Cold and Hot Bluing Process Explained

Bluing Steel Hot & Cold - Rust Protection - Easy To Follow DIY Guide #bluesteel #rustprotection

Metal bluing 3 ways

How to Blacken (or Blue) Steel Nuts and Bolts with Cold Bluing

Easy Quick Surface Protection for Steel Parts DIY #bluing #hotbluingsteel #surfaceprotection

Bluing a Clock Hand With a Heat Gun

HOT BLUING at home

Cold Bluing Steel Parts - Vise Clamps - Steel C45 Bluing Tutorial - OneGeekGuy

Spare Parts #12 - Heat Bluing A Set Of Steel Clock Hands

Cold Bluing A Vintage Axe During Restoration #giveaway #axe #restoration #vintage #tools #asmr

Cold Bluing Steel

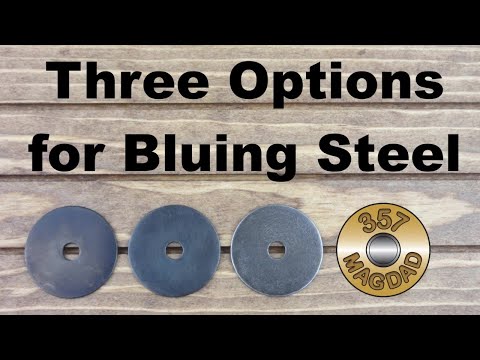

Three Options For Bluing Steel

Thermal Bluing Steel Watch Hands

How to Cold Blue a Rifle Barrel - woodworkweb

Hot Bluing - Rust Protecting Steel Parts

Cold Bluing Solutions Test: Super Blue, Oxpho-Blue, Formula 44/40, Oxpho-Blue Crème, Aluminum Black

Комментарии

0:06:28

0:06:28

0:01:00

0:01:00

0:00:44

0:00:44

0:02:27

0:02:27

0:16:16

0:16:16

0:06:29

0:06:29

0:00:40

0:00:40

0:01:40

0:01:40

0:09:59

0:09:59

0:10:27

0:10:27

0:10:47

0:10:47

0:02:57

0:02:57

0:00:27

0:00:27

0:01:16

0:01:16

0:04:34

0:04:34

0:10:39

0:10:39

0:10:15

0:10:15

0:00:17

0:00:17

0:05:21

0:05:21

0:09:59

0:09:59

0:09:30

0:09:30

0:11:09

0:11:09

0:05:38

0:05:38

0:05:23

0:05:23