filmov

tv

How To Drill Acrylic And Other Brittle Plastics

Показать описание

A brief shop tip on how to drill clean holes in acrylic and other plastics.

How To Drill Acrylic And Other Brittle Plastics

How to easily drill plexiglass, lexan and acrylic sheets

HOW TO: Drill Perspex, Acrylic and Polycarbonate

DIY: How to Drill Acrylic

Drilling PLEXIGLAS®: Perfectly drilled holes in just a few steps

HOW TO: Drill Acrylic

How NOT to Drill Acrylic #shorts #fail #diy

How I Cut & Drill Clear Acrylic (aka Plexiglass)

I Messed up Again!! || Acrylic Duck Tips || Aura Nails Using Pigment Powder || Acrylic Application

HOW TO: Drill Perspex Acrylic & Polycarbonate

Drill Bits For Drilling Plastic Acrylic Plexiglas Perspex Laminate Smooth Clean Hole No Cracking

How to Use Acrylic Nail Drill Bits

Step Drill Bit Plexi Holes for Gyford LEDs

Drill Acrylic Sump and Connect External Pump

How to Drill Holes in Acrylic | DIY Acrylic Sign | Copper Stand for Wedding Signs

How to drill a hole into acrylic plastic

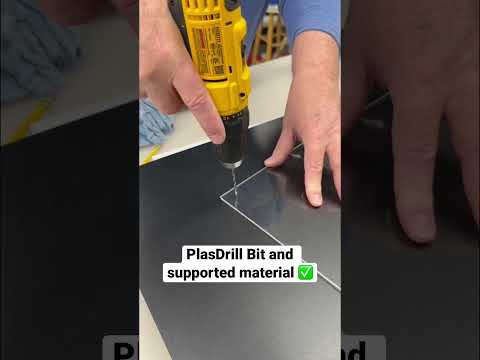

Regular vs. Acrylic Drill Bits

How to drill and cut acrylic sheet.

How to cut acrylic plastic rod / drill a hole in the end of a plastic rod

Drill acrylic | Drill Perspex | Drill Plexiglas

How to use an E-file Nail Drill on Acrylic Nails

How to drill acrylic * Acrylglas bohren

How Drill Acrylic without it Cracking

How to drill acrylic using soldering iron for pc part

Комментарии

0:05:42

0:05:42

0:03:11

0:03:11

0:02:09

0:02:09

0:01:03

0:01:03

0:03:45

0:03:45

0:03:14

0:03:14

0:00:16

0:00:16

0:05:00

0:05:00

0:14:55

0:14:55

0:00:58

0:00:58

0:14:36

0:14:36

0:09:01

0:09:01

0:00:30

0:00:30

0:08:46

0:08:46

0:05:39

0:05:39

0:01:54

0:01:54

0:00:08

0:00:08

0:02:53

0:02:53

0:02:23

0:02:23

0:04:40

0:04:40

0:06:16

0:06:16

0:09:45

0:09:45

0:01:35

0:01:35

0:03:04

0:03:04