filmov

tv

The Science Of Small Distances

Показать описание

We explore the precise measurement and machining of small distances and their importance on modern industrial society. The history of the meter and distance measurements are explained as well as intuitive examples of small distances given, moving from mm scales to the realm of microns. Further, we discuss some of the engineering issues that emerge as we try to machine at smaller tolerances such as fitment, assembly, and thermal expansion.

SUPPORT NEW MIND ON PATREON

SUPPORT NEW MIND ON PATREON

The Science Of Small Distances

Measurement of extremely small distances

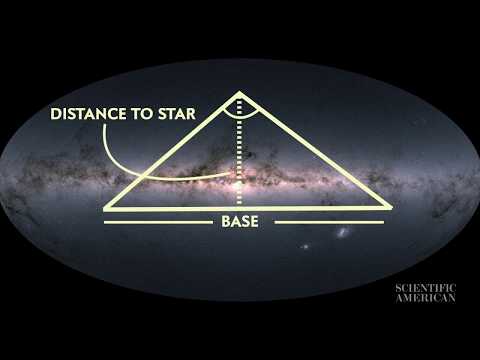

How Do We Measure the Distance to Stars?

Light seconds, light years, light centuries: How to measure extreme distances - Yuan-Sen Ting

Estimation of Very Small Distances & Ex-2.5 || Ch 2 Units and Measurement || Std 11 Physics || N...

Units and Measurement Class 11 Physics - Measurement Of Small Distances Size Of Molecules

How to estimate very small distances- atomic distances

#Physicsforclass11 (Physical World And MeasurementsP8) -Indirect Method For Measuring Small Distance

Myseries of the Sacred Universe - The Solar System in three dimensions (Chapter 4) #hinducosmology

Estimation of small distances and Range of length

Size, Distance, and Time in the Universe | Soft-Spoken ASMR (3.5 Hours)

Measurement of extremely small distances

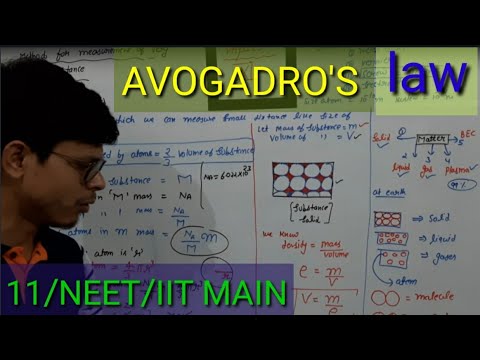

Indirect method for measuring small distances - Avogadro's hypothesis

Measuring! | Mini Math Movies | Scratch Garden

AVOGADRO'S AND RUTHERFORD LAW FOR MEASUREMENT OF VERY SMALL DISTANCES

Indirect method for measuring small distances

P1- Measuring Distances in Space (Parallax and Brightness)

Solar System Size and Distance

Measurement of small distances

2.3.2 Estimation of very small distances :Size of a molecule ch-2 class 11

🚀 Motion and Measurement of Distance | Class 6 Science #kidslearning

Estimation of Very Small Distances & Range of Lengths (Chapter 2: Units and Measurement (Part-3)...

Units and Measurements 03|| Estimation of a very small distances|| Sharwan sir

The Planck Length Explained in 90 Seconds! | Smallest Distance

Комментарии

0:13:31

0:13:31

0:04:32

0:04:32

0:02:16

0:02:16

0:05:29

0:05:29

0:20:07

0:20:07

0:07:03

0:07:03

0:06:34

0:06:34

0:16:43

0:16:43

0:08:23

0:08:23

0:13:44

0:13:44

3:33:25

3:33:25

0:04:32

0:04:32

0:04:56

0:04:56

0:07:44

0:07:44

0:49:30

0:49:30

0:10:34

0:10:34

0:07:11

0:07:11

0:01:21

0:01:21

1:16:29

1:16:29

0:14:56

0:14:56

0:06:13

0:06:13

0:21:10

0:21:10

0:03:01

0:03:01

0:01:39

0:01:39