filmov

tv

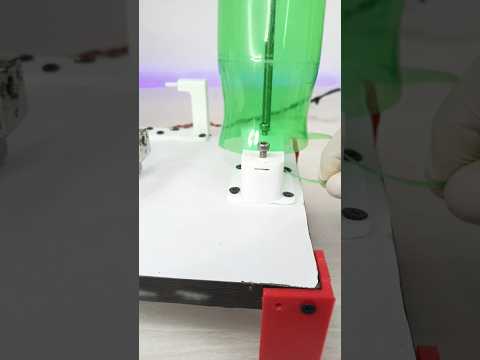

Make Filament From Plastic Bottles | PET filament 3d print settings

Показать описание

How to recycle any pet bottle into 3d printer filament + tips and tricks + PET 3d printer settings

Disclaimer: This tutorial is meant for educational purposes only. I am not responsible for any injuries or damages caused by the use of these techniques.

Recreator by @JRT3D - Build Guide + STLs

PETmachine by @TylmanDesign - Build Kit + STLs:

PullStruder M1 by @blake3dcake - STLs:

Hot Glue Gun Design by @lets_make

PET Print Settings by OkWeird5779

Disclaimer: This tutorial is meant for educational purposes only. I am not responsible for any injuries or damages caused by the use of these techniques.

Recreator by @JRT3D - Build Guide + STLs

PETmachine by @TylmanDesign - Build Kit + STLs:

PullStruder M1 by @blake3dcake - STLs:

Hot Glue Gun Design by @lets_make

PET Print Settings by OkWeird5779

Make Filament From Plastic Bottles | PET filament 3d print settings

This machine turns plastic bottles into filament for 3D printing!

MAKING FILAMENT #diy #shorts

I Turned Plastic Water Bottles Into 3D Printer Filament - The full journey

PET Bottle Recycling: Waste to 3D Printing Filament

PET-Machine, make Your own 3D printer filament from plastic bottles at home (DIY!)

make filament #shorts #diy

Making 3D filament: 9 minutes per bottle of manual processing, 3 minutes for this process

Sunday Live @ Five

How to make Filament for a 3D printer from plastic bottles

Make High Quality 3D Printing Filament From PET Plastic Bottles

Transforming Waste Plastic Bottle into 3D Printed Masterpiece

Create Your own Free 3D Printing Filament from Plastic Bottles Using This Incredible PET Machine!

I Turned Plastic Water Bottles Into 3D Printer Filament 🖨️💦🐢 PART 1

how I make filament with plastic bottles #how #3d #3dprinting #recycle #3dprinter #petg filamento

♻️How To Make Filament From Plastic Bottles 🥤

How to Make a Machine to Transform Plastic Bottles into Filament for 3D Printers.

This machine turns water bottles into 3D printer filament | Polyformer

Reliable and cleaner method for PET filament splicing #3dprinting #3dprint #artillerysidewinderx2

♻️ From plastic bottle to 3D printed happy sitting pot. thing:4891643

PET filament from plastic bottles! #recycle #3dprinting

PET Filament Machine

How to make bottle filament with glue gun without electronics

3D print waste RECYCLED

Комментарии

0:06:12

0:06:12

0:00:54

0:00:54

0:00:45

0:00:45

0:17:21

0:17:21

0:17:37

0:17:37

0:08:59

0:08:59

0:00:16

0:00:16

0:00:53

0:00:53

1:44:07

1:44:07

0:00:43

0:00:43

0:01:12

0:01:12

0:00:31

0:00:31

0:08:23

0:08:23

0:01:01

0:01:01

0:00:15

0:00:15

0:00:50

0:00:50

0:17:22

0:17:22

0:03:11

0:03:11

0:02:48

0:02:48

0:00:59

0:00:59

0:00:55

0:00:55

0:00:31

0:00:31

0:10:37

0:10:37

0:00:32

0:00:32