filmov

tv

What is a Gas Turbine? (For beginners)

Показать описание

▶ Check out the full blog post over at

=============================

Two of the most common applications of Gas Turbines in modern industries are Turbo Generators and Turbo Compressors.

We try to approach a Gas Turbo Generator (GTG) to better feel the subject.

In a Gas Turbine Power Plant, there’s a Generator which is an electrical machine. But to generate electricity this generator needs a Prime Mover which for my example is a Gas Turbine.

Gas Turbine transforms the chemical energy in the fuel (i.e. natural gas or the similar fuel) into mechanical energy.

The mechanical energy generated by the Turbine exit shaft is then transferred through a gearbox to the Generator’s shaft. Now my generator can create electrical energy.

This primitive form of electrical energy normally has a low or medium level of voltage and to better manage the power loss in transmission lines, this voltage should be increased by step-up transformers.

Such transformers give an adequate level of voltage to the electrical energy to be transmitted through the transmission lines and delivered to the grid.

After this brief overview of a sample Gas Turbine application, I’m going to dig down into the Gas Turbine mechanism in more detail.

First, imagine a rocket in which some fuel is going to burn and create a high-pressure exhaust gas. Based on energy conservation law, the chemical energy of the fuel is transformed into mechanical energy in the high-pressure exhaust gas.

When a rocket is fired, the thrust of this exhaust gas moves the rocket forward. This amount of rocket science is enough for me and now suppose I fix the rocket body with a robust mechanical structure to prevent its movement.

What will happen? The high-pressure exhaust gas should be released and it will have no way but backward!

Now keep this structure in mind and imagine I put a set of turbine blades in the path of this high-pressure back-fired exhaust.

You see that the release of mechanical energy which is mostly in a “linear” backward direction will mostly transform into kind of “rotational” movement of turbine shaft and so far I’d say it’s a big success, i.e. transforming the chemical energy of fuel gas into rotational mechanical energy of turbine shaft.

Now I have a “Prime Mover” for my generator in the above power plant example. Also, this prime mover concept can be used in different applications like turbo compressors or the likes.

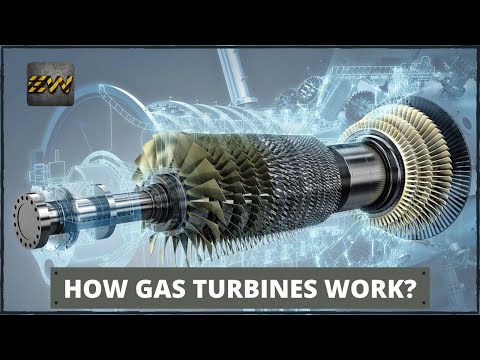

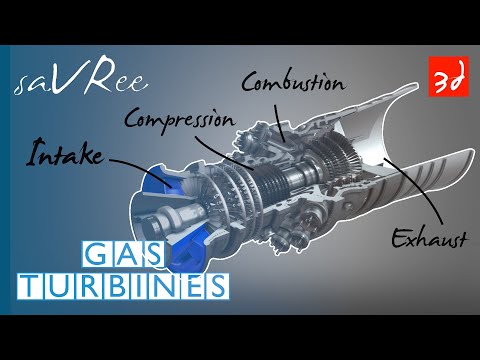

Now that I got the basics of Gas Turbines, let’s focus on a modern Gas Turbine and its components.

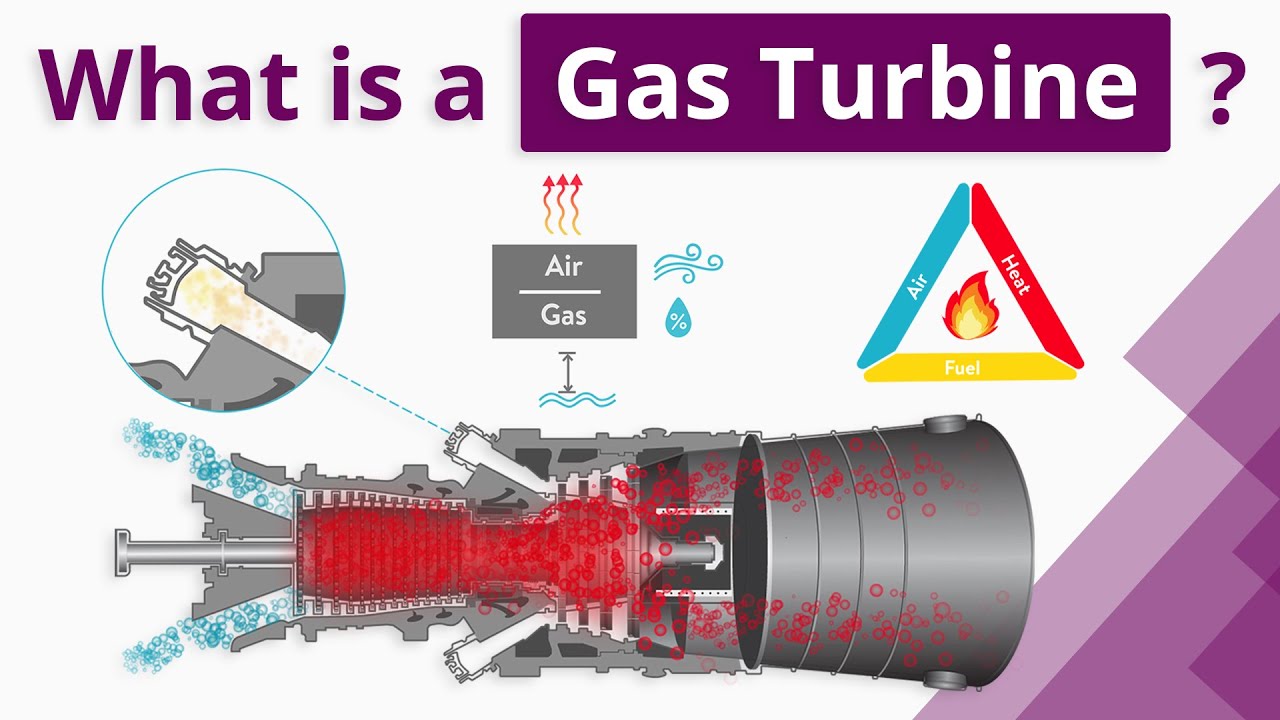

Most likely you know about “Fire Triangle” or “Combustion Triangle” which illustrates the necessary ingredients of fire or combustion, i.e. “Fuel”, “Air”, and “Heat”.

To transform the chemical energy of the fuel gas into mechanical energy, the fuel should be burnt in the “Combustion Chamber” of a gas turbine, so I need air and heat added to the fuel.

Air is let into the gas turbine through “Air Intake” and mixed with a proper amount of natural gas. The Air/Gas ratio is determined based on the specific heating value of the gas and quality of the air, amount of moisture, altitude from sea level and so on.

Now an ignition system steps in and makes the initial sparks, so hereby heat is provided. When the fire is established and stabilized in the combustion chamber, the ignition system will be put out of service.

The most critical process in normal turbine operation is to manage the combustion and produce a proper amount of high-pressure exhaust gas. This exhaust gas is applied to the turbine blades and after rotating the turbine shaft, conducted to the exhaust stack.

This was the simplest way to address major parts of Gas Turbines and as one of the most sophisticated man-made machines, a Gas Turbine deserves more elaboration.

Also, there are different technologies which some manufacturers use as their proprietary technology and were not considered in this video.

=============================

Missed our most recent videos? Watch them here:

=============================

To stay up to date with our last videos and more lessons, make sure to subscribe to this YouTube channel:

=============================

=============================

#RealPars #Gasturbine #Turbocompressor

Комментарии

0:02:40

0:02:40

0:09:35

0:09:35

0:01:16

0:01:16

0:01:13

0:01:13

0:03:29

0:03:29

0:16:09

0:16:09

0:04:54

0:04:54

0:04:28

0:04:28

0:00:37

0:00:37

0:04:20

0:04:20

0:03:38

0:03:38

0:00:58

0:00:58

0:00:26

0:00:26

0:01:00

0:01:00

0:01:15

0:01:15

0:08:53

0:08:53

0:03:01

0:03:01

0:00:07

0:00:07

0:00:11

0:00:11

0:00:17

0:00:17

0:04:14

0:04:14

0:00:39

0:00:39

0:00:19

0:00:19

0:00:22

0:00:22