filmov

tv

Left Hand Internal Acme Thread part one

Показать описание

Description

Metric lathe

Set up to cut Imperial threads

Metric lathe

Set up to cut Imperial threads

Cutting Internal & External Left Hand Acme Threads on the Metal Lathe

Left Hand Internal Acme Thread part one

Single Point Cutting Internal Left Hand Acme Thread on the Metal Lathe

CHOOSE YOUR OWN ADVENTURE: Single Point ACME Threading!

Cutting Internal Left Hand Acme Threads on the Lathe: Monarch Lathe Restoration - Part 28

Left Hand Internal ACME Thread part 3

Single Point Threading an Internal Left Hand 5 Pitch Acme Thread for a LeBlond Lathe Nut

How to: Internal ACME Threading

Machining Parts With Internal LH Acme Threads

Cutting Left-Hand Acme Threads on the Metal Lathe

Left Hand Internal ACME Thread part 2

A left-hand internal acme thread for the cross-slide nut to fix backlash-Part 2

Cutting Internal Acme Threads on the Metal Lathe

How to Determine the hole size for an Internal Thread -- SHOP GEM !!

Cutting Internal ACME Threads on a Metal Lathe

More Acme Nut Threading

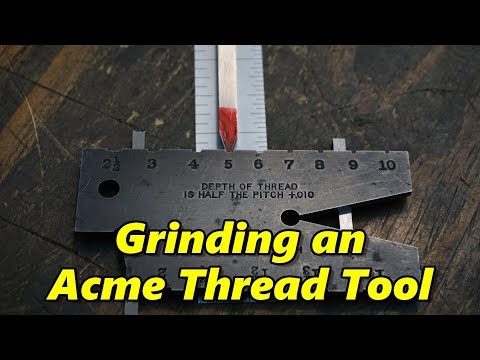

Hand Grinding Acme Thread Tool Bit

A left-hand internal acme thread for the cross slide nut to fix backlash-Part 1

Double Lead Left Handed ID Acme Threads

Single point left handed Acme thread machining

Horizontal Boring Mill: Making a new Lead Screw Nut with Internal Left Hand Acme Threads - Part 1

Horizontal Boring Mill: Making a new Lead Screw Nut with Internal Left Hand Acme Threads - Part 2

Turning trapezoidal thread (ACME) in stainless steel on the Mazak Nexus 350MY

Screw cutting an internal Acme thread.

Комментарии

0:24:14

0:24:14

0:17:35

0:17:35

0:18:28

0:18:28

0:12:42

0:12:42

0:32:15

0:32:15

0:14:01

0:14:01

0:22:15

0:22:15

0:14:43

0:14:43

0:16:45

0:16:45

0:23:04

0:23:04

0:20:11

0:20:11

0:12:18

0:12:18

0:20:31

0:20:31

0:02:46

0:02:46

0:28:49

0:28:49

0:13:02

0:13:02

0:24:35

0:24:35

0:12:48

0:12:48

0:25:39

0:25:39

0:01:38

0:01:38

0:24:44

0:24:44

0:10:10

0:10:10

0:01:24

0:01:24

0:13:45

0:13:45