filmov

tv

Screw cutting an internal Acme thread.

Показать описание

Struggling to find time to edit videos - this job was done in December '22 (hence the long sleeves & background noise from a space heater) & I can't remember exactly what it was for! The original brass block was completely worn out & the screw was pretty worn also so I tried to just make the new block(s) to suit the old screw.

The blocks were machined to size & drilled in the centre in a milling machine, before being held in a four jaw chuck on our Colchester Triumph 2000 lathe for threading using the Ainjest rapid screw cutting attachment.

The blocks were machined to size & drilled in the centre in a milling machine, before being held in a four jaw chuck on our Colchester Triumph 2000 lathe for threading using the Ainjest rapid screw cutting attachment.

Screw cutting an internal Acme thread.

Cutting Internal Acme Threads on the Metal Lathe

CHOOSE YOUR OWN ADVENTURE: Single Point ACME Threading!

ACME Internal Threading #manualmachining

Cutting Internal ACME Threads on a Metal Lathe

Internal Screw Cutting . Blind Hole

Machining Parts With Internal LH Acme Threads

Cutting Internal & External Left Hand Acme Threads on the Metal Lathe

Bullet build - Internal ACME thread part 2, Screw cutting in the lathe

More Acme Nut Threading

SNNC 563 Internal Acme Screw Cutting. Doubleboost Caps For Sale.

Single Point Threading an Internal Left Hand 5 Pitch Acme Thread for a LeBlond Lathe Nut

ACME Thread Tool ready to rock!

How to make tapered Acme thread

Single-point threading an Acme cross-slide nut

How To Cut Internal Threads On A Lathe

Cutting Internal Left Hand Acme Threads on the Lathe: Monarch Lathe Restoration - Part 28

Internal Acme Threading? Making a Float-Lock Vise, Part 2!

Thread Milling

Carbide thread milling cutter, Acme thread

Single Point Cutting Internal Left Hand Acme Thread on the Metal Lathe

How To Pickup an Internal Thread for Repairs !!!

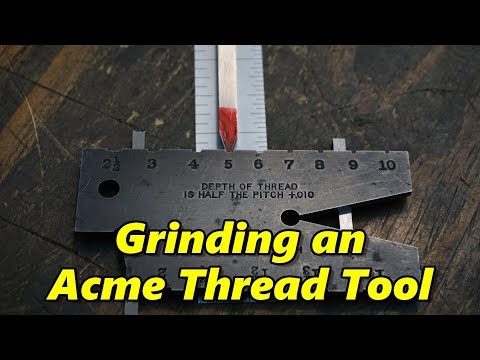

Hand Grinding Acme Thread Tool Bit

this how internet acme thread cut in gunmetal

Комментарии

0:13:45

0:13:45

0:20:31

0:20:31

0:12:42

0:12:42

0:00:14

0:00:14

0:28:49

0:28:49

0:06:30

0:06:30

0:16:45

0:16:45

0:24:14

0:24:14

0:14:58

0:14:58

0:13:02

0:13:02

0:20:47

0:20:47

0:22:15

0:22:15

0:00:15

0:00:15

0:00:16

0:00:16

0:03:27

0:03:27

0:17:17

0:17:17

0:32:15

0:32:15

0:24:22

0:24:22

0:00:20

0:00:20

0:00:14

0:00:14

0:18:28

0:18:28

0:19:51

0:19:51

0:24:35

0:24:35

0:00:12

0:00:12