filmov

tv

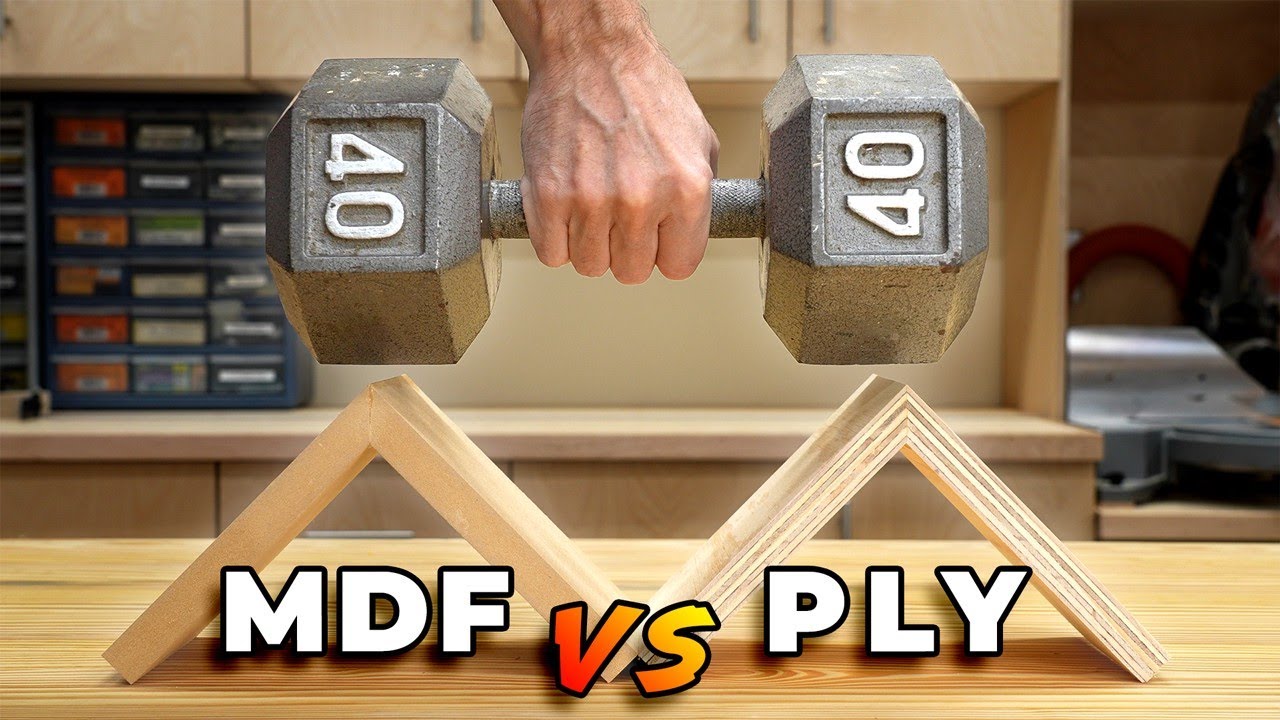

Testing MDF vs Plywood - What to Buy?

Показать описание

Can you use MDF and save money vs plywood? I put MDF and plywood through 10 tests to find out!

Thanks to Woodcraft for sponsoring this video!

🎥 What to Watch Next:

➤Plans from this video:

More content, early access, FREE plans, video credits

➤Tools/Supplies Used (affiliate):

➤Support the FTBT Channel:

➤Thank you to these partners for supporting my channel. Go check them out!

➤FOLLOW ME on Social Media:

0:00 The Contenders

0:30 Weigh In

2:00 Strength Test

3:50 Make MDF Shelves 2X Stronger

4:22 Finishing Test

6:21 Wetability Test

8:59 Workability Test

11:08 Why I Hate MDF

12:55 Stability & Flatness

13:57 How to Store Sheet Goods

14:41 Fastener Friendliness Test

17:00 Robustness Test

18:40 Joint Strength Test

22:16 The Results

Thanks to Woodcraft for sponsoring this video!

🎥 What to Watch Next:

➤Plans from this video:

More content, early access, FREE plans, video credits

➤Tools/Supplies Used (affiliate):

➤Support the FTBT Channel:

➤Thank you to these partners for supporting my channel. Go check them out!

➤FOLLOW ME on Social Media:

0:00 The Contenders

0:30 Weigh In

2:00 Strength Test

3:50 Make MDF Shelves 2X Stronger

4:22 Finishing Test

6:21 Wetability Test

8:59 Workability Test

11:08 Why I Hate MDF

12:55 Stability & Flatness

13:57 How to Store Sheet Goods

14:41 Fastener Friendliness Test

17:00 Robustness Test

18:40 Joint Strength Test

22:16 The Results

Testing MDF vs Plywood - What to Buy?

MDF VS. PLYWOOD (Which Is Better?? Pros + Cons!!)

I was wrong about MDF...

How strong is plywood, MDF, OSB, particle board vs. solid wood

Film-faced Plywood vs Moisture-resistant MDF water immersion test

Melamine vs. Raw MDF, water, oil and screws what holds up best

Water DAMAGE on Kitchen Cabinets? (Plywood / MDF Ultra / MDF / Particleboard)

PLYWOOD vs MDF For Speaker Building - Tests Show Surprising Results

MDF vs PLYWOOD - Which is BETTER for my Project?

Why we choose to use Plywood VS MDF Water Test

Making the Right Choice: Particle Board vs MDF vs Plywood | Creative Design Studios

PUNCH TEST GONE WRONG - Plywood vs Particle Board vs MDF

Strength Test MDF vs WOOD

Tricoya Vs Moisture Resistant MDF 24 Hour Water Test

MDF vs. PLY. Which one makes the speaker sound better? #speaker #audio

MDF Verses Water Resistant MDF | Woodworking

MDF Explained

Just how ‘toxic’ is MDF, exactly?? [video #290]

Water Absorption Test|MDF|HDF|WPC|Pvc Board or Plywood Which one is better for Home Interior 🤔HDHMR...

MDF - strength test

MDF Vs Plywood Cabinets | Which Is More Supportive? [2024]

MDF vs Plywood

The Ultimate Showdown: Plywood vs MDF - Does it Impact Sound Quality?

MDF material testi #mdf #test #capcut #trendingshorts

Комментарии

0:22:54

0:22:54

0:11:36

0:11:36

0:16:14

0:16:14

0:06:26

0:06:26

0:01:35

0:01:35

0:10:22

0:10:22

0:02:58

0:02:58

0:09:30

0:09:30

0:04:28

0:04:28

0:00:41

0:00:41

0:02:57

0:02:57

0:04:53

0:04:53

0:01:01

0:01:01

0:01:00

0:01:00

0:00:33

0:00:33

0:14:02

0:14:02

0:00:32

0:00:32

0:13:21

0:13:21

0:26:51

0:26:51

0:00:40

0:00:40

0:04:56

0:04:56

0:03:16

0:03:16

0:00:58

0:00:58

0:00:33

0:00:33