filmov

tv

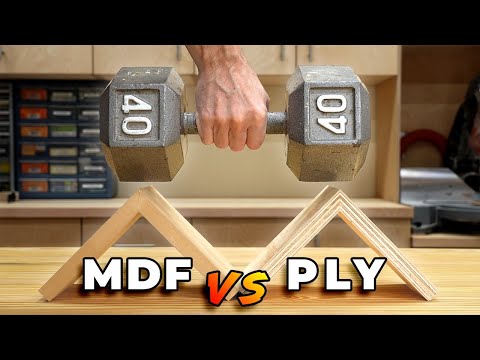

MDF VS. PLYWOOD (Which Is Better?? Pros + Cons!!)

Показать описание

Check Out Our FREE GUIDE: *25 Must-Have Carpentry Tools...Under $25 Each!*

Affiliate Tool Links:

Dewalt Titanium Drill bits:

Milwaukee Drill/Driver Combo:

Bosch 12-amp Router:

Dewalt 12" Sliding Compound Miter Saw:

(These are affiliate links. When you shop through these links, we receive a small commission at NO EXTRA CHARGE TO YOU. We greatly appreciate the support!)

FOLLOW US ON INSTAGRAM:

FOLLOW US ON LINKEDIN:

CHECK OUT MORE HONEST CARPENTER VIDEOS:

Amazing Flexible Window Screens:

PVC Trim Vs. Wood Trim:

The Truth About Wood Rot:

MDF or PLYWOOD? Which material is better? What are the Pros and Cons of both? Most DIYers want to know these things. In this video, The Honest Carpenter breaks down the similarities and differences between MDF and Plywood!

Both MDF and plywood are used in a variety of projects--but they mostly are used to build shelving, built-ins and cabinets. They can also be used in paneling projects.

They are both made of wood byproducts and glue. But, Plywood is made of actual wood layers, or "veneers"; each layer runs 90 degrees to the layers above and below it. MDF is made from fine wood pulp and glue--it's kind of like cake batter that gets pressed into a sheet.

COST: MDF is generally a bit cheaper than plywood, about $35 per sheet. But, plywood comes in a huge variety of grades and types, with prices all over the place. Sandeply and radiata pine plywood tend to be reasonably priced, under $40. But cabinet-grade plywoods, like birch, maple and oak, can be up to $65 per sheet.

STRENGTH: Plywood is much stronger than MDF because of the cross-laid grain layers.

DURABILITY: Plywood is also more durable than MDF for this same reason. The corners hold up better--they don't get dinged or bent as badly.

WORKABILITY: They both respond to tools in a similar fashion. MDF will produce sharper, cleaner cuts than plywood, which tends to tear out. Both can be drilled with drill bits. But, plywood holds a screw much better, especially in the edge. MDF edges should basically never been fastened into without extra support.

DUST CONTROL: Plywood makes dust similar to other lumber. But, MDF makes terrible dust! It's like a powder. Be sure to wear a respirator and hook up vacuum filtration for your cuts.

INTERIOR / EXTERIOR: Plywood comes in both grades. But MDF is really an interior material. The wood pulp fibers make it soak up water like a sponge. It will bloat and rot quickly.

On the whole, I like plywood a lot more. But, MDF is a decent cheap alternative, and it also is very FLAT, which is one of its main advantages over plywood.

Thanks for watching! Be sure to visit us at THE HONEST CARPENTER website:

Affiliate Tool Links:

Dewalt Titanium Drill bits:

Milwaukee Drill/Driver Combo:

Bosch 12-amp Router:

Dewalt 12" Sliding Compound Miter Saw:

(These are affiliate links. When you shop through these links, we receive a small commission at NO EXTRA CHARGE TO YOU. We greatly appreciate the support!)

FOLLOW US ON INSTAGRAM:

FOLLOW US ON LINKEDIN:

CHECK OUT MORE HONEST CARPENTER VIDEOS:

Amazing Flexible Window Screens:

PVC Trim Vs. Wood Trim:

The Truth About Wood Rot:

MDF or PLYWOOD? Which material is better? What are the Pros and Cons of both? Most DIYers want to know these things. In this video, The Honest Carpenter breaks down the similarities and differences between MDF and Plywood!

Both MDF and plywood are used in a variety of projects--but they mostly are used to build shelving, built-ins and cabinets. They can also be used in paneling projects.

They are both made of wood byproducts and glue. But, Plywood is made of actual wood layers, or "veneers"; each layer runs 90 degrees to the layers above and below it. MDF is made from fine wood pulp and glue--it's kind of like cake batter that gets pressed into a sheet.

COST: MDF is generally a bit cheaper than plywood, about $35 per sheet. But, plywood comes in a huge variety of grades and types, with prices all over the place. Sandeply and radiata pine plywood tend to be reasonably priced, under $40. But cabinet-grade plywoods, like birch, maple and oak, can be up to $65 per sheet.

STRENGTH: Plywood is much stronger than MDF because of the cross-laid grain layers.

DURABILITY: Plywood is also more durable than MDF for this same reason. The corners hold up better--they don't get dinged or bent as badly.

WORKABILITY: They both respond to tools in a similar fashion. MDF will produce sharper, cleaner cuts than plywood, which tends to tear out. Both can be drilled with drill bits. But, plywood holds a screw much better, especially in the edge. MDF edges should basically never been fastened into without extra support.

DUST CONTROL: Plywood makes dust similar to other lumber. But, MDF makes terrible dust! It's like a powder. Be sure to wear a respirator and hook up vacuum filtration for your cuts.

INTERIOR / EXTERIOR: Plywood comes in both grades. But MDF is really an interior material. The wood pulp fibers make it soak up water like a sponge. It will bloat and rot quickly.

On the whole, I like plywood a lot more. But, MDF is a decent cheap alternative, and it also is very FLAT, which is one of its main advantages over plywood.

Thanks for watching! Be sure to visit us at THE HONEST CARPENTER website:

Комментарии

0:11:36

0:11:36

0:22:54

0:22:54

0:02:57

0:02:57

0:04:28

0:04:28

0:16:14

0:16:14

0:02:55

0:02:55

0:01:01

0:01:01

0:00:41

0:00:41

0:00:13

0:00:13

0:00:16

0:00:16

0:04:56

0:04:56

0:02:16

0:02:16

0:01:01

0:01:01

0:05:46

0:05:46

0:02:58

0:02:58

0:05:43

0:05:43

0:06:22

0:06:22

0:01:56

0:01:56

0:09:44

0:09:44

0:03:16

0:03:16

0:00:27

0:00:27

0:06:05

0:06:05

0:00:54

0:00:54

0:08:37

0:08:37