filmov

tv

Metal Alloys of the Future?

Показать описание

High Entropy Alloys are a fascinating new area of research, so today we're going to try and make some HEA nanoparticles and explain what makes this research so exciting

🥰 CONSIDER SUBSCRIBING 🥰

==== Resources ====

==== Timeline ====

0:00 Intro

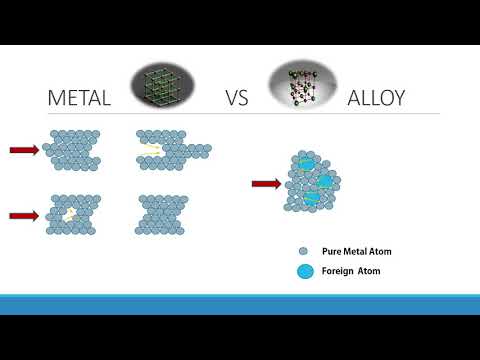

0:38 Traditional Alloying

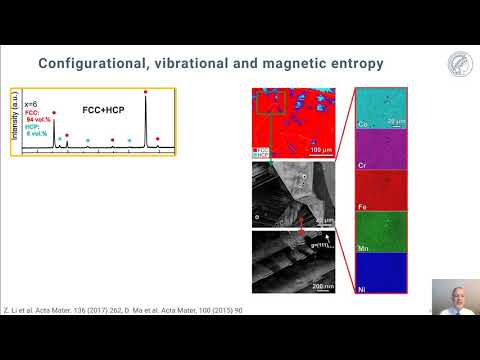

2:37 High Entropy Alloys

4:55 Fabrication

7:43 Results

8:30 Large Particles

9:31 Small Particles

11:07 Almost HEA but not quite

11:52 Cross-section

12:46 Success!

🥰 CONSIDER SUBSCRIBING 🥰

==== Resources ====

==== Timeline ====

0:00 Intro

0:38 Traditional Alloying

2:37 High Entropy Alloys

4:55 Fabrication

7:43 Results

8:30 Large Particles

9:31 Small Particles

11:07 Almost HEA but not quite

11:52 Cross-section

12:46 Success!

Metal Alloys of the Future?

How a metal with a memory will shape our future on Mars

High-entropy alloys: The future of alloying

Why graphene hasn’t taken over the world...yet

How NASA Reinvented The Wheel

This metal is more valuable than gold

What are high entropy alloys?

Alloys: Types and Examples

The Metal That Remembers - Nitinol

High-Entropy Alloys: The Future of Materials

An introduction to high entropy alloys

High entropy alloys The future of alloying

Shape-Memory Alloys: The Metals of the Future #science #physics

Shape-Memory Alloys: The Metals of the Future PART 2 #science #physics

307 L8 Mechanics of titanium alloys #2, other Ti alloys

The Material Science of Metal 3D Printing

Shape Memory Alloys: Engineering's Future

Combinatorial Design of High entropy Alloys

PURE METAL, ALLOYS AND SUPERCONDUCTORS - BEGINNERS GUIDE (IGCSE & SPM)

Metal ,alloys, superalloys, and metal parts

Magnesium Alloys and The Future of Automotives (ft. Dr. Dikai Guan) | Ep. 37

3D Printing Stronger Metal Alloys | RRR Ep. 10

CREATING A NEW METAL ALLOY FOR JEWELRY?!?!? #shorts

high entropy alloys

Комментарии

0:15:25

0:15:25

0:06:13

0:06:13

0:02:27

0:02:27

0:07:43

0:07:43

0:25:34

0:25:34

0:07:00

0:07:00

0:26:27

0:26:27

0:04:22

0:04:22

0:05:11

0:05:11

0:00:57

0:00:57

0:54:07

0:54:07

0:02:27

0:02:27

0:00:51

0:00:51

0:00:52

0:00:52

0:47:24

0:47:24

0:15:00

0:15:00

0:00:57

0:00:57

0:29:06

0:29:06

0:06:21

0:06:21

0:00:11

0:00:11

0:42:08

0:42:08

0:00:55

0:00:55

0:01:00

0:01:00

0:00:16

0:00:16