filmov

tv

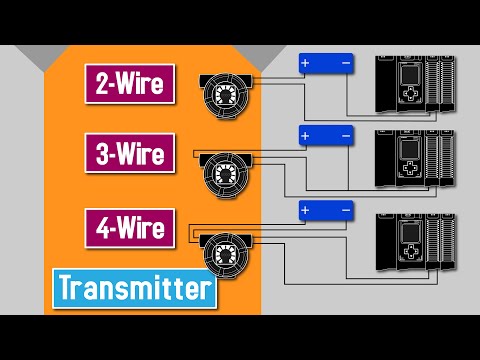

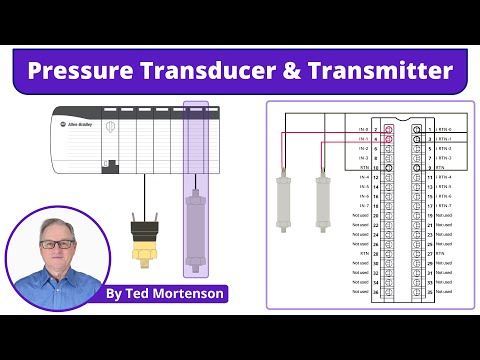

PLC Analog Inputs and Signals

Показать описание

==========================

✅ Check out the full blog post over at

==========================

In this video, we are going to be talking about analog inputs to the PLC.

What do we mean by analog input? Analog values are continuous values, such as temperatures and pressures.

While we tend to think of them in digital terms, at some point we have to convert them from the continuous world into our digital world, and this is where analog inputs come in.

Voltage signals in the range of plus or minus 20 volts or so and current signals in milliamps are commonly used as both analog inputs to PLCs.

Every PLC manufacturer has I/O modules to deal with these kinds of signals, along with other, more specialized modules.

==========================

Missed our most recent videos? Watch them here:

=============================

To stay up to date with our last videos and more lessons, make sure to subscribe to this YouTube channel:

=============================

=============================

=============================

A special thanks to Frederico Duarte Fagundes for translating this video.

#RealPars #PLC #PLCanaloginput

Комментарии

0:08:55

0:08:55

0:03:15

0:03:15

0:03:25

0:03:25

0:07:44

0:07:44

0:09:02

0:09:02

0:04:56

0:04:56

0:19:30

0:19:30

0:08:13

0:08:13

0:05:30

0:05:30

0:03:40

0:03:40

0:00:39

0:00:39

0:07:46

0:07:46

0:06:52

0:06:52

0:06:27

0:06:27

0:05:44

0:05:44

0:04:22

0:04:22

0:25:29

0:25:29

0:05:08

0:05:08

0:14:41

0:14:41

0:18:16

0:18:16

0:01:25

0:01:25

0:06:45

0:06:45

0:06:38

0:06:38

0:20:50

0:20:50