filmov

tv

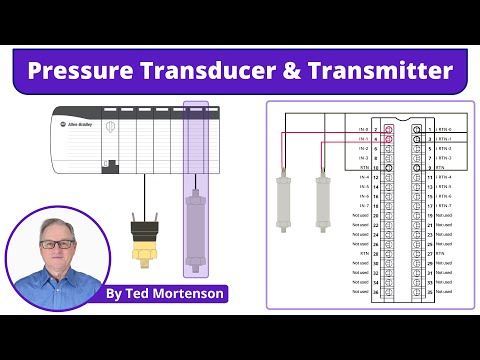

Pressure Transducer and Transmitter Wiring Explained

Показать описание

▶ You can read the full post here

⌚Timestamps:

00:00 - Intro

00:35 - Transducer and transmitter

01:04 - Pressure switch

01:23 - Pressure transmitter

01:41 - Pressure transmitter wiring

02:34 - Wiring pressure switch to PLC

03:51 - Wiring pressure transmitter to PLC

06:07 - Wiring example

=============================

In this video, we’re going to show you how to wire a few different transducers and transmitters to digital and analog PLC input modules.

We’re also going to analyze a typical instrument field-wiring drawing to show you how PLCs are properly configured for different transducer and transmitter types.

A transducer is a device that converts one form of energy to an electrical or electronic signal.

A Pressure switch is a two-part device consisting of a sensing transducer and an electrical switch.

A pressure switch is a digital device because it has only two possible conditions – open or closed. It is therefore connected to a PLC digital input module.

A Pressure Transmitter is a two-part device consisting of a sensing transducer and a circuit that transmits a standard instrumentation electrical signal representing a physical variable being measured. In most applications, the electrical signal is 4 to 20 mA.

A Pressure Transmitter is an analog device and is therefore connected to a PLC analog input module.

Many people refer to this device as a Transducer. For the sake of simplicity, we’ll continue to refer to it as a Transmitter.

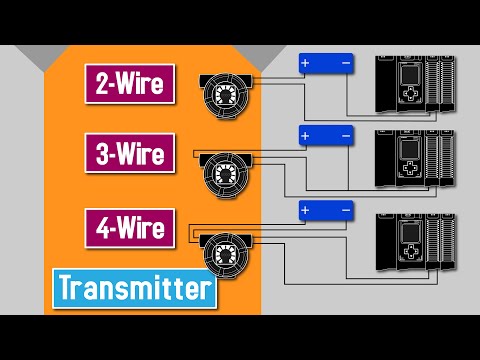

A Pressure Transmitter requires a power supply to operate. Most Pressure Transmitters are two-wire types. Transmitters are also available as four-wire types.

As the name suggests, a two-wire pressure transmitter has only two wires. These two wires provide power for the transmitter and are also the signal lines!

A four-wire transmitter has two wires connected to a power supply and two signal wires connected to the PLC. The power supply can be AC or DC depending on the vendor and model.

1) Digital input – 1756-IF8

We will wire a Gems PS41 series pressure switch to Input 3 of a ControlLogix 1756-IB32 digital input module.

The 1756-IB32 module is capable of supporting up to 32 digital input devices. Each additional device would be wired the same as the Gems pressure switch.

2) Analog input – Single-ended and differential

The analog module can be wired in two possible modes: Single-ended or Differential.

The selection is important as it determines how the module is physically wired.

In Single-Ended mode, we can connect 8 two-wire transmitters sharing one power supply. Each transmitter connection is referred to as a Channel.

2) Analog input – 1756-IF8

The 1756-IF8 module is configured for current input during programming in the I/O configuration.

We will connect the Wika E-11 two-wire transmitter to Channel 5 of a ControlLogix 1756-IF8 analog module.

2) Analog input – 1756-IF8 - an industry example

Field wiring diagrams vary between companies. In our example, two channels of the 1756-IF8 are wired in Single-Ended Mode.

We’ll look at how Pressure Transmitter ZT-P3606 is connected to Channel 0, and ZT-P3610 is connected to Channel 1. Both transmitters share the same +24V DC Power Supply.

=============================

=============================

Missed our most recent videos? Watch them here:

=============================

To stay up to date with our last videos, make sure to subscribe to this YouTube channel:

=============================

=============================

#RealPars #Transducer #Industry

Комментарии

0:08:13

0:08:13

0:00:19

0:00:19

0:08:26

0:08:26

0:03:50

0:03:50

0:00:46

0:00:46

0:01:55

0:01:55

0:07:07

0:07:07

0:04:31

0:04:31

0:02:11

0:02:11

0:03:20

0:03:20

0:07:44

0:07:44

0:00:16

0:00:16

0:02:11

0:02:11

0:05:33

0:05:33

0:02:38

0:02:38

0:00:15

0:00:15

0:06:31

0:06:31

0:00:43

0:00:43

0:00:29

0:00:29

0:00:18

0:00:18

0:02:08

0:02:08

0:00:30

0:00:30

0:02:18

0:02:18

0:00:33

0:00:33