filmov

tv

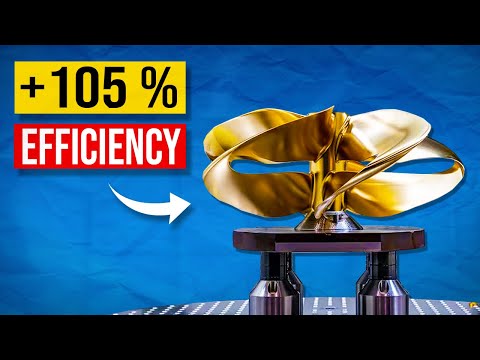

Toroidal propellers - thrust and noise analysis. So, is it worth using them?

Показать описание

The thrust analyses were done using 6S batteries. All the noise analyses were done using 4S batteries.

----------------------------------------------------------------------------------------------------------------------------

STRIKING FPV models:

----------------------------------------------------------------------------------------------------------------------------

00:00 – Introduction

00:23 –The propellers under analysis

01:33 –The measurement system

02:24 –Thrust analysis and results

03:39 – Noise analysis

03:48 – Classical 3-blade propeller

04:15 – Bi-Loop Toroidal propeller

04:53 – Tri-Blade Toroidal propeller

05:21 – Noise analysis results

06:19 – Conclusions

----------------------------------------------------------------------------------------------------------------------------

╔═╦╗╔╦╗╔═╦═╦╦╦╦╗╔═╗

╠╗║╚╝║║╠╗║╚╣║║║║║═╣ I Really Appreciate Your Support!

╚═╩══╩═╩═╩═╩╝╚╩═╩═╝

----------------------------------------------------------------------------------------------------------------------------

STRIKING FPV models:

----------------------------------------------------------------------------------------------------------------------------

00:00 – Introduction

00:23 –The propellers under analysis

01:33 –The measurement system

02:24 –Thrust analysis and results

03:39 – Noise analysis

03:48 – Classical 3-blade propeller

04:15 – Bi-Loop Toroidal propeller

04:53 – Tri-Blade Toroidal propeller

05:21 – Noise analysis results

06:19 – Conclusions

----------------------------------------------------------------------------------------------------------------------------

╔═╦╗╔╦╗╔═╦═╦╦╦╦╗╔═╗

╠╗║╚╝║║╠╗║╚╣║║║║║═╣ I Really Appreciate Your Support!

╚═╩══╩═╩═╩═╩╝╚╩═╩═╝

Foxeer Donut 5145 Toroidal Propellers - Overview, Thrust Tests & Flight Footage

Toroidal propellers - thrust and noise analysis. So, is it worth using them?

Propeller of the future?!

Why Ducted Fans are more energy efficient than Propellers

Toroidal Propeller & Simple Propeller thrust Capacity comparison

This Genius Propeller Will Change Transport Forever

Toroidal propellers testing on dji avata #toroidal #djiavata #toroidalprops #toroidalproppellers

Do Toroidal Propellers Actually Work? #3dprinting @QIDITech

Who WINS the SILENT Propeller WAR?

The Unexpected Genius of Bionic Propellers

Toroidal propeller vs 3D printed EDF

Testing MIT's Toroidal Drone Propeller Design & Sound #shorts

MIT Toroidal Propeller Testing - Performance, Efficiency, and Response - PETG + PLA

TOROIDAL PROPS on a Drone - This is Huge!!

Testing a TOROIDAL propeller UNDERWATER

Cooling Fan: Toroidal vs Normal

Are Toroidal Propellors Better Than Regular Propellers

Toroidal vs Regular Propeller for RC Plane

Drone Propulsion - The LATEST Breakthroughs!

The Unexpected Genius of Contra-Rotating Propellers

How Do Zipline's Silent Propellers Work?

The Genius of Cycloidal Propellers: Future of Flight?

toroidal propeller, just one wing.

Toroidal Prop Testing: Is this the future of FPV propellers?!

Комментарии

0:12:47

0:12:47

0:07:20

0:07:20

0:00:47

0:00:47

0:00:51

0:00:51

0:04:33

0:04:33

0:05:18

0:05:18

0:00:15

0:00:15

0:00:59

0:00:59

0:06:44

0:06:44

0:11:48

0:11:48

0:08:35

0:08:35

0:01:00

0:01:00

0:06:20

0:06:20

0:07:51

0:07:51

0:08:30

0:08:30

0:03:46

0:03:46

0:00:58

0:00:58

0:01:00

0:01:00

0:07:03

0:07:03

0:11:09

0:11:09

0:10:13

0:10:13

0:11:36

0:11:36

0:00:12

0:00:12

0:14:55

0:14:55