filmov

tv

Co2 Vs C25 mig gas: Lets test the differences

Показать описание

In this episode we tackle experiments with C02 gas.

0:00:00 Intro and book learning

0:05:29 lets weld, and inspect those welds

0:13:20 Conclusion

0:00:00 Intro and book learning

0:05:29 lets weld, and inspect those welds

0:13:20 Conclusion

C02 VS C25 Gas for MIG Welding on a Professional Miller Welder

C02 VS C25 Gas for MIG Welding With a High End Hobby Lincoln Electric Welder

C02 VS C25 Gas for MIG Welding on a Budget Harbor Freight Titanium 140 Welder

How to Choose the Best Shielding Gas for MIG Welding

Co2 Vs C25 mig gas: Lets test the differences

120V Vulcan MIG Welder Testing: C25, CO2 and Flux Core

100% CO2 vs C25 gas: strength testing

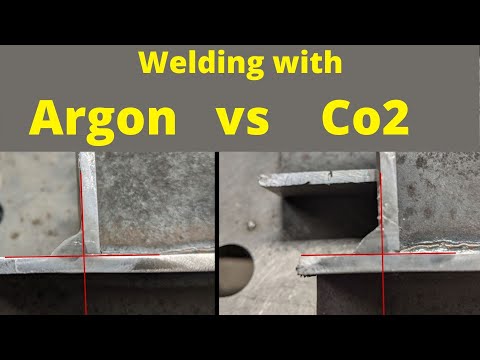

Mig welding with Argon and Co2 [ Etch Testing]

Welding Fume 100% CO2 vs 75%Ar/25%CO2

🔥 MIG Welding with 100% CO2

Mig welding stainless er309l + 75/25 argon/co2 and also er308 + trimix (90% helium)

How to Choose the Right Welding Gas - Kevin Caron

Mig welding CO2 Normal voltage ⚡#co2 #hard #mig #tecnical #welding #work #how #ms #steel #tigweld

Tech Tips: Shielding Gas Selection for MIG Welding

Mig welding with Argon and Co2 😘👉🇰🇷

mig welding CO2 high voltage ⚡#mistakes #welding #co2 #tecnical #hardwork #work #hard #mig

How NOT to Buy Welding Gas | An Expensive Lesson in Shielding Gas

YOU WONT LEARN THIS IN WELDING SCHOOL WHICH GAS IS REALLY BEST FOR YOUR MIG WELDER

co2 gas for mig welding #shorts #yuotubeshorts #shortvideo

Basic mig welding technique for beginners

Different Shielding Gases and How They Change Your Weld

MIG Weld Stainless Steel with C25 Gas

beginner's way of mig welding

MIG Welders Beware! - 'Pretty' Does NOT Equal Strong. - Weld Analysis

Комментарии

0:03:43

0:03:43

0:04:01

0:04:01

0:03:39

0:03:39

0:01:16

0:01:16

0:18:03

0:18:03

0:08:23

0:08:23

0:19:34

0:19:34

0:10:43

0:10:43

0:04:52

0:04:52

0:08:12

0:08:12

0:00:24

0:00:24

0:04:47

0:04:47

0:00:31

0:00:31

0:02:13

0:02:13

0:00:27

0:00:27

0:00:53

0:00:53

0:05:48

0:05:48

0:08:27

0:08:27

0:00:08

0:00:08

0:00:16

0:00:16

0:09:00

0:09:00

0:08:15

0:08:15

0:00:48

0:00:48

0:04:22

0:04:22