filmov

tv

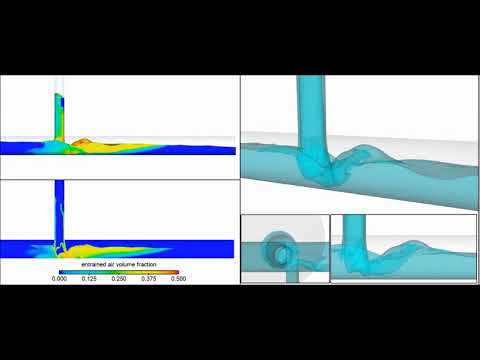

Air Entrainment Explained

Показать описание

Sections :

00:00 – Introduction

01:02 – Airlock Explanation

02:29 – Airlock Causes

04:34 – Difference Between Airlock and Mild Cavitation

05:29 – Tips to Control Airlock

10:39 - Conclusion

Air Entrainment – A distant cousin of Cavitation

Imagine that you are stuck in a locked room, wanting to go out but there is no escape. How much torture would that be for you? That is the amount of torture that the liquid experiences when air or vapor gets entrapped in a pump system.

Let us discuss about Airlock, how it occurs in the pump system, what are its causes and effects and 4 tips on how to control them, so that you can consider applying them in your pump system rightaway.

References:

Suction Side Problems – Gas Entrainment by James. H. Ingram

Air Release Valve

Vortex Impeller

Inducer

Side Channel Pump

Side Channel Impeller

Choi, Won & Yoo, Il & Park, Mu & Chung, Myung. (2013). Experimental study on the effect of blade angle on regenerative pump performance. Proceedings of the Institution of Mechanical Engineers, Part A: Journal of Power and Energy. 227. 585-592. 10.1177/0957650913487731.

Side Channel Operating Principle - Sero Pumps

Kryptonite

CC0 - Audio :

Vortex Diagram – Pump World 1978 Edititon

Attributions: Licensed under CC

00:00 – Introduction

01:02 – Airlock Explanation

02:29 – Airlock Causes

04:34 – Difference Between Airlock and Mild Cavitation

05:29 – Tips to Control Airlock

10:39 - Conclusion

Air Entrainment – A distant cousin of Cavitation

Imagine that you are stuck in a locked room, wanting to go out but there is no escape. How much torture would that be for you? That is the amount of torture that the liquid experiences when air or vapor gets entrapped in a pump system.

Let us discuss about Airlock, how it occurs in the pump system, what are its causes and effects and 4 tips on how to control them, so that you can consider applying them in your pump system rightaway.

References:

Suction Side Problems – Gas Entrainment by James. H. Ingram

Air Release Valve

Vortex Impeller

Inducer

Side Channel Pump

Side Channel Impeller

Choi, Won & Yoo, Il & Park, Mu & Chung, Myung. (2013). Experimental study on the effect of blade angle on regenerative pump performance. Proceedings of the Institution of Mechanical Engineers, Part A: Journal of Power and Energy. 227. 585-592. 10.1177/0957650913487731.

Side Channel Operating Principle - Sero Pumps

Kryptonite

CC0 - Audio :

Vortex Diagram – Pump World 1978 Edititon

Attributions: Licensed under CC

Комментарии

0:11:47

0:11:47

0:01:54

0:01:54

0:01:32

0:01:32

0:01:50

0:01:50

0:00:41

0:00:41

0:09:55

0:09:55

0:05:00

0:05:00

0:00:25

0:00:25

1:04:04

1:04:04

0:20:55

0:20:55

0:03:20

0:03:20

0:06:35

0:06:35

0:25:24

0:25:24

0:00:32

0:00:32

0:01:44

0:01:44

0:08:09

0:08:09

0:21:28

0:21:28

0:00:22

0:00:22

0:00:16

0:00:16

0:01:40

0:01:40

0:02:41

0:02:41

0:04:44

0:04:44

0:01:42

0:01:42

0:01:19

0:01:19