filmov

tv

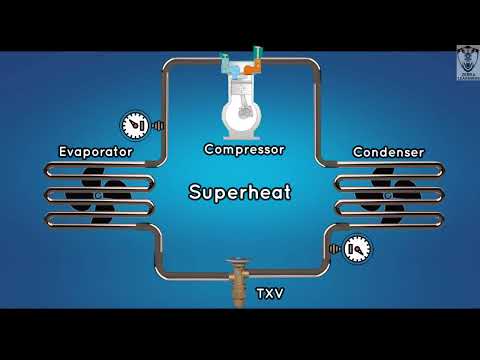

Finding Target Superheat

Показать описание

Bert teaches the Kalos techs some strategies for finding target superheat on systems with fixed-orifice metering devices (not TXVs).

Whenever we take readings, we should start by knowing what we want our readings to look like; we should know what to expect of a system that is working properly so that we can recognize abnormalities in our readings. Superheat is an especially critical reading because it can let us know a system's risk of flooding the compressor, if the evaporator coil is being fed efficiently (as opposed to overfed or underfed), and the evaporator load, and it can help us diagnose problems with TXVs (on TXV systems). We can measure superheat on the suction line or discharge line, but those superheat values are very different and can tell us different things about the system.

Suction line superheat readings that are too high can indicate that we are starving the evaporator, and low superheat readings can indicate that the system is feeding too much refrigerant into the evaporator coil (or that the coil is otherwise not absorbing heat sufficiently). When you have a metering device problem, like a wide-open TXV, the saturation point is a lot higher than it should be because the pressure stays higher and keeps the evaporator coil warmer.

A common rule of thumb is to achieve a 10-degree target superheat for fixed-orifice systems, but the target is variable because the superheat isn't constantly monitored and manipulated by the metering device (unlike a TXV system). On a fixed-orifice system, the target superheat will decrease as the outdoor dry-bulb temperature increases.

Whenever we take readings, we should start by knowing what we want our readings to look like; we should know what to expect of a system that is working properly so that we can recognize abnormalities in our readings. Superheat is an especially critical reading because it can let us know a system's risk of flooding the compressor, if the evaporator coil is being fed efficiently (as opposed to overfed or underfed), and the evaporator load, and it can help us diagnose problems with TXVs (on TXV systems). We can measure superheat on the suction line or discharge line, but those superheat values are very different and can tell us different things about the system.

Suction line superheat readings that are too high can indicate that we are starving the evaporator, and low superheat readings can indicate that the system is feeding too much refrigerant into the evaporator coil (or that the coil is otherwise not absorbing heat sufficiently). When you have a metering device problem, like a wide-open TXV, the saturation point is a lot higher than it should be because the pressure stays higher and keeps the evaporator coil warmer.

A common rule of thumb is to achieve a 10-degree target superheat for fixed-orifice systems, but the target is variable because the superheat isn't constantly monitored and manipulated by the metering device (unlike a TXV system). On a fixed-orifice system, the target superheat will decrease as the outdoor dry-bulb temperature increases.

Комментарии

0:10:44

0:10:44

0:15:58

0:15:58

0:09:22

0:09:22

0:16:03

0:16:03

0:02:39

0:02:39

0:05:22

0:05:22

0:13:18

0:13:18

0:04:23

0:04:23

0:19:45

0:19:45

0:05:10

0:05:10

0:05:46

0:05:46

0:07:57

0:07:57

0:02:32

0:02:32

0:05:48

0:05:48

0:11:36

0:11:36

0:05:10

0:05:10

0:04:11

0:04:11

0:06:04

0:06:04

0:04:44

0:04:44

0:14:14

0:14:14

0:04:28

0:04:28

0:02:44

0:02:44

0:08:20

0:08:20

0:18:48

0:18:48