filmov

tv

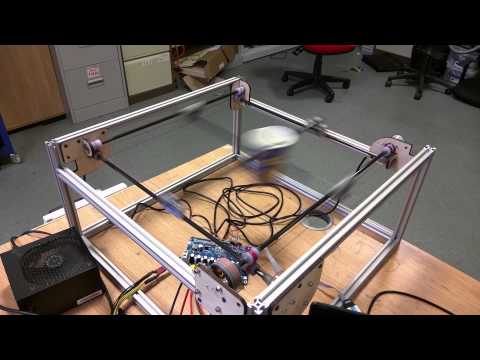

Speed & Position Control – DC Gear Motor with Encoder | MOT 6

Показать описание

It’s time to make the motor project more practical. Let’s use a DC motor with integrated encoder module and gearbox – This motor can deliver a lot more torque than the previous one! While testing this hardware, we also improve the control loop running on the ATMEGA328P (Arduino Nano).

#Motor #Encoder #PID

Next topics: Control Improvements & Modbus Integration

–

Links:

Support EE for Everyone:

Amazon Associate Links (featured products – paid links):

“As an Amazon Associate, I earn from qualifying purchases.”

0:00 Introduction

0:40 Open Loop Speed Control

2:05 Speed and Position Control

4:00 Improved Controller Performance

4:31 Conclusion

6:53 Attempt at Improved Position Control

#Motor #Encoder #PID

Next topics: Control Improvements & Modbus Integration

–

Links:

Support EE for Everyone:

Amazon Associate Links (featured products – paid links):

“As an Amazon Associate, I earn from qualifying purchases.”

0:00 Introduction

0:40 Open Loop Speed Control

2:05 Speed and Position Control

4:00 Improved Controller Performance

4:31 Conclusion

6:53 Attempt at Improved Position Control

Комментарии