filmov

tv

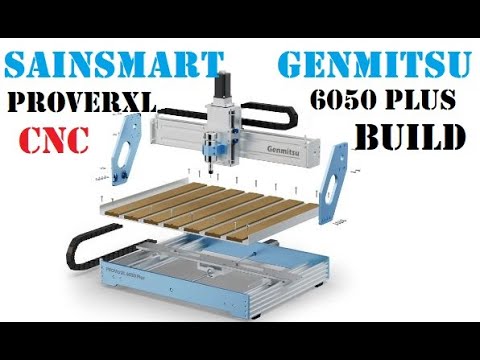

Building the Genmitsu PROVerXL 6050 Plus CNC from Sainsmart

Показать описание

Intro 00:00

Start assembling 01:58

Connecting and first test 15:23

I have recently set up a Patreon page to help keep making tutorials and keep my YouTube channel moving forward.

If you want to help but do not want to become a Patreon, you con contribute directly:

Some product links I use are affiliate links. This means they do not cost you any more but I might make a small commission in return which helps towards making these videos.

Building the Genmitsu PROVerXL 6050 Plus CNC from Sainsmart

SainSMART Genmitsu PROVerXL 6050 Plus CNC Router Mechanical Kit Build

Sainsmart Genmitsu PROVerXL 6050 CNC Full Assembly

Sainsmart Genmitsu PROVerXL 6050 Plus Cnc - Full Build

Sainsmart 6050 Cnc with Linear Rails - (Sainsmart Genmitsu PROVerXL 6050 Plus)

How to Install the Laser Module on the Genmitsu PROVerXL 6050 Plus

Sainsmart Genmitsu PROVerXl 6050 Plus CNC machine review

Genmitsu PROVerXL 6050 Plus CNC Router Machine, Our Next-generation PROVerXL in a New Form Factor

Testing the Genmitsu PROVerXL 6050 Plus CNC Router

Assembling the Genmitsu PROVerXL 6050 Plus CNC router

Sainsmart Genmitsu 6050 CNC Machine PROVar XL

GENMITSU PROVerXL 6050 Plus CNC Router, 15mm linear rails, 20mm linear rods, 130 lbs. 300W spindle

THE BEST value BUDGET CNC Router SainSMART Genmitsu PROVerXL 6050 Plus

BEST CNC Router under $1800 SainSMART Genmitsu PROVerXL 6050 Plus UNBOXING

Absolute best value CNC machine to buy Sainsmart Genmitsu PROVerXL 6050 plus

Assembly Guide for PROVerXL 6050 Plus

CNC Router Electrical build SainSMART Genmitsu PROVerXL 6050 Plus

Make a wooden horse rocking chair with CNC, Genmitsu PROVerXL 6050 Plus

Quick upgrade to the @sainsmart Genmitsu PROVerXL 6050 Plus

SainSMART Genmitsu PROVerXL 6050 Plus (UGS) Setup The BEST FREE Universal G-Code Sender

PROVerXL 6050 Plus vs 6060 extended original - Sainsmart CNC machines

10 Differences Between CNC Spindles & Routers (I Use Both)

Cutting aluminum with the Genmitsu 6050 PROver XL plus

First Test Drive SainSMART Genmitsu PROVerXL 6050 Plus, (first machining job) part 2

Комментарии

0:26:55

0:26:55

0:31:58

0:31:58

0:22:30

0:22:30

0:05:08

0:05:08

0:24:40

0:24:40

0:01:16

0:01:16

0:17:16

0:17:16

0:00:47

0:00:47

0:18:09

0:18:09

0:00:48

0:00:48

0:12:28

0:12:28

0:24:37

0:24:37

0:09:36

0:09:36

0:31:25

0:31:25

0:08:20

0:08:20

0:01:09

0:01:09

0:14:04

0:14:04

0:00:19

0:00:19

0:00:08

0:00:08

0:21:32

0:21:32

0:07:47

0:07:47

0:11:39

0:11:39

0:24:29

0:24:29

0:15:16

0:15:16