filmov

tv

EEVblog #1037 - Solving Ceramic Capacitor Cracking

Показать описание

Dave demonstrates various practical PCB and component selection solutions and techniques to prevent flex stress cracking of Multi Layer Ceramic Capacitors (MLCC) on PCB's and preventing your product from catching on fire!

Open Mode capacitors.

Flexible Endcap Soft Termination Capacitors

Lead Frame Capacitors

Series Capacitors

TDK Solutions for Ceramic Capacitor Cracking

Soft Termination:

AVX Flexiterm:

Kemet Flex Termination

Support the EEVblog through Patreon!

Donate With Bitcoin & Other Crypto Currencies!

EEVblog Amazon Store (Dave gets a cut):

Open Mode capacitors.

Flexible Endcap Soft Termination Capacitors

Lead Frame Capacitors

Series Capacitors

TDK Solutions for Ceramic Capacitor Cracking

Soft Termination:

AVX Flexiterm:

Kemet Flex Termination

Support the EEVblog through Patreon!

Donate With Bitcoin & Other Crypto Currencies!

EEVblog Amazon Store (Dave gets a cut):

EEVblog #1037 - Solving Ceramic Capacitor Cracking

EEVblog #855 - Ceramic Capacitor Piezoelectric Effect

EEVblog #1038 - Uni-T UPO2104CS Oscilloscope Teardown

EEVblog #1034 - Mailbag

EEVblog #1043 - Mailbag

EEVblog #932 - How Does A HV Differential Probe Work?

Full Discussion - Film Capacitor Failures with Ron Demcko from AVX

EEVblog #1036 - PSU Fire PCB Repair

EEVblog #812 - Varta 15min NiMH Charger Part 2

EEVblog #865 - How To Increase Alkaline Battery Capacity

EEVblog #1117 - PCB Power Plane Capacitance

Why Use AA's Instead of 9V Batteries in Multimeters?

Ceramic capacitor overvoltage 1

Vented capacitor overvoltage 1

voltage spikes on ground side of ceramic capacitors lepton 2.0

EEVblog #1045 - How To Drive an LCD

eevBLAB #25 - IEEE Maker Contest Extreme FAIL!

EEVblog #1035 - Flaming DIY Power Supply!

EEVblog #843 - David's rPrint 3D Printer Design

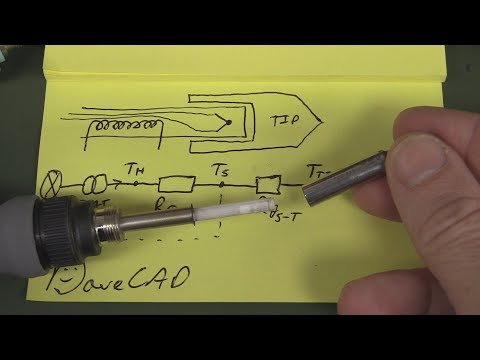

EEVblog #1065 - Soldering Iron Power Delivery Explained

EEVblog #1099 - BattBump Kickstarter REDACTED EDITION!

EEVblog 1464 - TOP 5 Jellybean Comparators

removing Mlcc's for gold recovery

EEVblog #1365 - Viewer PCB & Circuit Design Review

Комментарии

0:28:41

0:28:41

0:26:48

0:26:48

0:32:53

0:32:53

0:42:04

0:42:04

0:45:51

0:45:51

0:24:35

0:24:35

1:23:56

1:23:56

0:19:10

0:19:10

0:37:47

0:37:47

0:13:53

0:13:53

0:30:46

0:30:46

0:11:27

0:11:27

0:00:24

0:00:24

0:00:12

0:00:12

0:00:49

0:00:49

0:21:45

0:21:45

0:08:23

0:08:23

0:20:00

0:20:00

0:58:00

0:58:00

0:23:04

0:23:04

0:12:53

0:12:53

0:39:59

0:39:59

0:24:58

0:24:58

0:45:10

0:45:10