filmov

tv

GD&T Lesson 3: Orientation Tolerances

Показать описание

I discuss Parallelism, Perpendicularly and Angularity.

GD&T Lesson 3: Orientation Tolerances

GD&T Part 3 Orientation Tolerances

GD&T Orientation (Angularity, Perpendicularity, Parallelism)

GD&T - DimXpert Orientation Tolerances

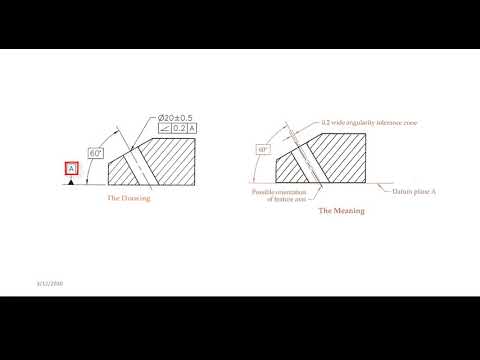

GD&T Angularity Introduction

GD&T, Angularity, Modifier Tangent plane, Angularity for Surface and Axis, Martin MB Bak

How to Apply GD&T Position Tolerance to a Hole

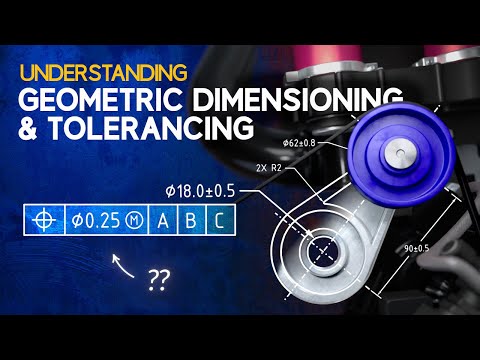

Understanding GD&T

NeuroMeasure5 - Orientation Tolerance

GD&T example: 2 parts with datums, position, and profile tolerance

GD&T: Parallelism Tolerance Zone

Angularity

Full GD&T - Profile Tolerancing

GD&T Symbol | 6_Perpendicularity | orientation tolerance| AutoCAD #drawing #autocad #tolerance

Orientation Tolerances I GD&T I Engineer

GD&T Common Mistakes: Overuse of Orientation and Form

GD & T explained #shorts

GD&T ASME Y14.5 Coplanarity Tolerances. Size, Form, Orientation and Profile

GD&T Parallelism Tolerance, Surface Application

GD&T: Profile vs Flatness

MDes24c GDT perpendicularity

Defining GD&T Controls: Form, Orientation, Location, Profile, and Runout | Symbols & Toleran...

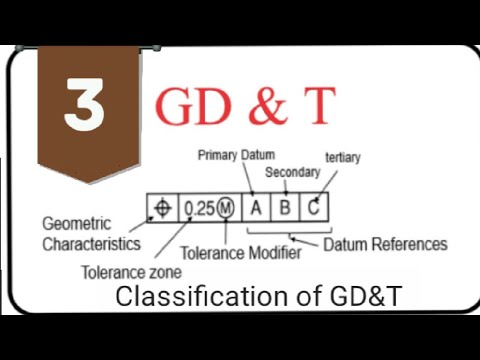

Basics of GD&T Part-3 |Classification of Geometric tolerances|

Does Runout or Size control the circularity/form error in GD&T? (It Depends)

Комментарии

0:23:56

0:23:56

0:03:24

0:03:24

0:05:45

0:05:45

0:16:07

0:16:07

0:01:42

0:01:42

0:06:34

0:06:34

0:03:16

0:03:16

0:29:32

0:29:32

0:04:22

0:04:22

0:05:07

0:05:07

0:01:47

0:01:47

0:13:19

0:13:19

0:04:44

0:04:44

0:00:21

0:00:21

0:06:18

0:06:18

0:07:05

0:07:05

0:00:23

0:00:23

0:06:55

0:06:55

0:03:58

0:03:58

0:07:03

0:07:03

0:10:35

0:10:35

1:05:06

1:05:06

0:00:49

0:00:49

0:15:14

0:15:14