filmov

tv

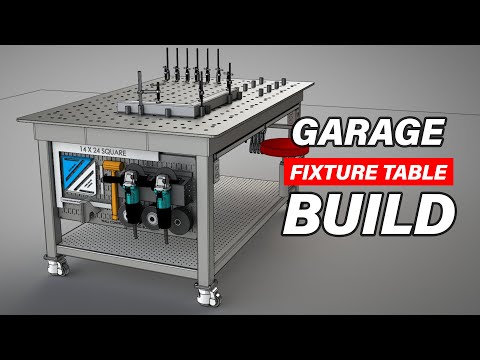

Building The Ultimate Welding/ Fab Table!!

Показать описание

Where I buy parts:

Sponsors/ Discounts:

Camera equipment used in the video!

Send me stuff!

PO Box 133

Chattaroy WA 99003

ULTIMATE DIY Welding Table

Building The Ultimate Welding/ Fab Table!!

Building The ULTIMATE Small Garage Welding and Fixture Table | CertiFlat Fab Block

THE ULTIMATE WELDING CART!!!

DIY Welding Fabrication Table - Stronghand On a Budget

The Ultimate Welding and Metal Fabrication Fixture Table Build!

ULTIMATE WELDING & METAL FAB TABLE WORKBENCH BUILD FROM SCRATH!!!

flux core welding done as a best quality

Homemade Welding Fixture Table + Storage Hack — Built for my Home Garage Shop

Ultimate Welding Station and Metal Fabrication

How to: Build an Ultimate Welding Table & Cart for Your Workshop

Build any size Welding Fabrication Fixture Table DIY Template Perfect Layout

2023 New Handheld Laser Welding Machine

Building The Ultimate Wood-Fired Camp Cooker | Double Rocket Stove Welding Project

ajjo welding kariye

90kg Welding Table Build

HOW TO BUILD $30 DIY welding fixture table. !!!!

BEST WELDING TOOLS YOU CAN MAKE!!!

Building My Dream Welding Table! DIY

Three secret thin metal welding tricks that not everyone knows

Welding Table Build / Elevating and Rolling / Aluminum and Stainless / Fabrication Table

Best Welding Fixture Table for Under $1,000?

How To Build The Ultimate Welding Table

Shop Organization DIY Building the Ultimate Welding Clamp Storage Rack

Комментарии

0:08:38

0:08:38

0:26:53

0:26:53

0:13:35

0:13:35

0:08:05

0:08:05

0:15:06

0:15:06

0:28:44

0:28:44

0:06:47

0:06:47

0:00:18

0:00:18

0:16:51

0:16:51

0:34:19

0:34:19

0:30:46

0:30:46

0:45:48

0:45:48

0:00:20

0:00:20

0:09:51

0:09:51

0:00:16

0:00:16

0:12:50

0:12:50

0:11:46

0:11:46

0:14:06

0:14:06

0:36:15

0:36:15

0:03:01

0:03:01

0:11:09

0:11:09

0:20:28

0:20:28

0:22:20

0:22:20

0:22:43

0:22:43