filmov

tv

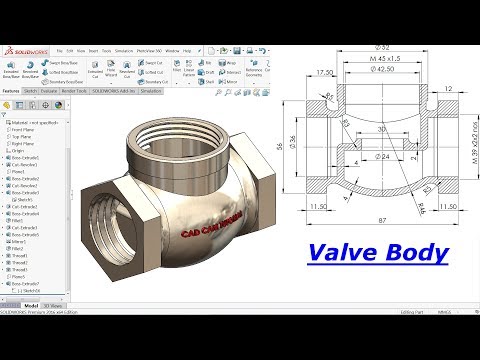

Types of Valves #cad #solidworks #fusion360 #mechanical #engineering #mechanism #3d #valve

Показать описание

Valves are mechanical devices used to control the flow and pressure of fluids (liquids, gases, or slurries) within a system. They can start, stop, regulate, or direct the flow of a fluid. Here are some common types of valves and their applications:

1. Gate Valve

Operation: A gate valve uses a flat or wedge-shaped gate that moves perpendicular to the flow to start or stop fluid flow. It's primarily used in fully open or fully closed positions.

Applications: Water supply systems, oil and gas pipelines.

2. Globe Valve

Operation: Globe valves use a disk that moves against the flow path to regulate fluid flow. They are ideal for throttling and frequent operation.

Applications: Steam applications, cooling water systems, fuel oil systems.

3. Ball Valve

Operation: A ball valve uses a spherical disc (ball) with a hole in it that aligns with the flow when open and is perpendicular to the flow when closed. It's known for quick shutoff.

Applications: Water, gas, oil pipelines, and systems where quick shutoff is essential.

4. Butterfly Valve

Operation: A butterfly valve uses a rotating disc to control the flow. The disc remains in the flow path, which makes it less suitable for throttling but excellent for quick shutoff.

Applications: Large-diameter pipelines, water treatment plants, fire protection systems.

5. Check Valve

Operation: A check valve allows fluid to flow in one direction only, preventing backflow. It opens with forward flow and closes automatically if the flow reverses.

Applications: Pump discharge lines, water and wastewater systems.

6. Diaphragm Valve

Operation: Diaphragm valves use a flexible diaphragm that moves up and down to regulate the flow. The diaphragm seals against the valve body to stop the flow.

Applications: Corrosive and abrasive fluid handling, water treatment plants.

7. Plug Valve

Operation: A plug valve uses a cylindrical or conically tapered plug with a hole in it that can be rotated to align with the flow path for open and closed positions.

Applications: Oil and gas industries, chemical processing.

8. Needle Valve

Operation: Needle valves have a small, tapered point at the end of a valve stem that moves in and out of a small seat to finely control flow.

Applications: Precision control of flow in gas and liquid systems, instrumentation, and sampling lines.

9. Pressure Relief Valve

Operation: A pressure relief valve automatically opens at a preset pressure to protect equipment from being exposed to pressures that exceed their design limits.

Applications: Boilers, pressure vessels, compressed air systems.

10. Solenoid Valve

Operation: Solenoid valves are electrically operated valves that use an electromagnetic solenoid to move the valve mechanism, allowing or stopping fluid flow.

Applications: Automated fluid control systems, HVAC systems, irrigation systems.

11. Pinch Valve

Operation: Pinch valves control the flow by pinching a flexible tube or hose, cutting off or allowing fluid flow. They are ideal for slurries and fluids with suspended solids.

Applications: Food processing, chemical handling, wastewater treatment.

12. Control Valve

Operation: Control valves modulate fluid flow by varying the size of the flow passage as directed by a controller, which responds to signals from sensors.

Applications: Process control in industries such as oil and gas, power generation, water treatment.

Each type of valve is chosen based on factors like the type of fluid, the need for flow control, the operating environment, and maintenance requirements.

---------------------------------------------------------------------------------------------

Rating, commenting, subscribing and sharing are always appreciated!!

----------------------------------------------------------------------------------------------

▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

Follow Us On:

#Education

#Fusion360

#Fusion360tutorial

#solidworks

#cad

#autodeskinventor

1. Gate Valve

Operation: A gate valve uses a flat or wedge-shaped gate that moves perpendicular to the flow to start or stop fluid flow. It's primarily used in fully open or fully closed positions.

Applications: Water supply systems, oil and gas pipelines.

2. Globe Valve

Operation: Globe valves use a disk that moves against the flow path to regulate fluid flow. They are ideal for throttling and frequent operation.

Applications: Steam applications, cooling water systems, fuel oil systems.

3. Ball Valve

Operation: A ball valve uses a spherical disc (ball) with a hole in it that aligns with the flow when open and is perpendicular to the flow when closed. It's known for quick shutoff.

Applications: Water, gas, oil pipelines, and systems where quick shutoff is essential.

4. Butterfly Valve

Operation: A butterfly valve uses a rotating disc to control the flow. The disc remains in the flow path, which makes it less suitable for throttling but excellent for quick shutoff.

Applications: Large-diameter pipelines, water treatment plants, fire protection systems.

5. Check Valve

Operation: A check valve allows fluid to flow in one direction only, preventing backflow. It opens with forward flow and closes automatically if the flow reverses.

Applications: Pump discharge lines, water and wastewater systems.

6. Diaphragm Valve

Operation: Diaphragm valves use a flexible diaphragm that moves up and down to regulate the flow. The diaphragm seals against the valve body to stop the flow.

Applications: Corrosive and abrasive fluid handling, water treatment plants.

7. Plug Valve

Operation: A plug valve uses a cylindrical or conically tapered plug with a hole in it that can be rotated to align with the flow path for open and closed positions.

Applications: Oil and gas industries, chemical processing.

8. Needle Valve

Operation: Needle valves have a small, tapered point at the end of a valve stem that moves in and out of a small seat to finely control flow.

Applications: Precision control of flow in gas and liquid systems, instrumentation, and sampling lines.

9. Pressure Relief Valve

Operation: A pressure relief valve automatically opens at a preset pressure to protect equipment from being exposed to pressures that exceed their design limits.

Applications: Boilers, pressure vessels, compressed air systems.

10. Solenoid Valve

Operation: Solenoid valves are electrically operated valves that use an electromagnetic solenoid to move the valve mechanism, allowing or stopping fluid flow.

Applications: Automated fluid control systems, HVAC systems, irrigation systems.

11. Pinch Valve

Operation: Pinch valves control the flow by pinching a flexible tube or hose, cutting off or allowing fluid flow. They are ideal for slurries and fluids with suspended solids.

Applications: Food processing, chemical handling, wastewater treatment.

12. Control Valve

Operation: Control valves modulate fluid flow by varying the size of the flow passage as directed by a controller, which responds to signals from sensors.

Applications: Process control in industries such as oil and gas, power generation, water treatment.

Each type of valve is chosen based on factors like the type of fluid, the need for flow control, the operating environment, and maintenance requirements.

---------------------------------------------------------------------------------------------

Rating, commenting, subscribing and sharing are always appreciated!!

----------------------------------------------------------------------------------------------

▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

Follow Us On:

#Education

#Fusion360

#Fusion360tutorial

#solidworks

#cad

#autodeskinventor

0:00:09

0:00:09

0:00:04

0:00:04

0:00:04

0:00:04

0:00:05

0:00:05

0:00:09

0:00:09

0:01:19

0:01:19

0:24:54

0:24:54

0:00:07

0:00:07

0:00:27

0:00:27

0:00:16

0:00:16

0:41:08

0:41:08

0:18:08

0:18:08

0:00:09

0:00:09

0:38:22

0:38:22

0:00:06

0:00:06

0:00:27

0:00:27

0:36:58

0:36:58

0:19:58

0:19:58

1:33:52

1:33:52

0:00:16

0:00:16

0:04:58

0:04:58

0:00:16

0:00:16

1:21:20

1:21:20

0:00:30

0:00:30