filmov

tv

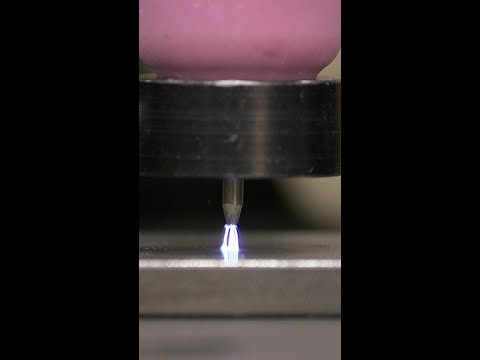

Can I Stick Weld Razor Blades? | Thin Steel Stick Welding Tips

Показать описание

A fun challenge to test the limits of stick welding thin metal while providing 4 practical tips.

Stick welding is great because of the simple equipment, portability and intuitive nature of the process. It is really well suited for thicker materials, where very thin material is a better fit for TIG welding or MIG welding. In this video, I explore how thin of material can be stick welded.

****Affordable self-paced welding courses taught by me****

****Where to Buy Practice Metal and Weld Kits****

USE DISCOUNT CODE 'TIMWELDS' TO SAVE 10%

****Where to Buy Top Quality Welding Machines and Accessories****

USE DISCOUNT CODE 'TIMWELDS' TO SAVE 5%

***Things you Might Like***

****Affiliate Notice****

Some of the links on this page are affiliate links which provide a small commission from sales to help support this channel and make these videos possible. Thanks for your support!

***Videos Mentioned***

Stick welding is great because of the simple equipment, portability and intuitive nature of the process. It is really well suited for thicker materials, where very thin material is a better fit for TIG welding or MIG welding. In this video, I explore how thin of material can be stick welded.

****Affordable self-paced welding courses taught by me****

****Where to Buy Practice Metal and Weld Kits****

USE DISCOUNT CODE 'TIMWELDS' TO SAVE 10%

****Where to Buy Top Quality Welding Machines and Accessories****

USE DISCOUNT CODE 'TIMWELDS' TO SAVE 5%

***Things you Might Like***

****Affiliate Notice****

Some of the links on this page are affiliate links which provide a small commission from sales to help support this channel and make these videos possible. Thanks for your support!

***Videos Mentioned***

Комментарии

0:10:31

0:10:31

0:01:15

0:01:15

0:00:10

0:00:10

0:01:40

0:01:40

0:00:14

0:00:14

0:00:38

0:00:38

0:00:27

0:00:27

0:04:46

0:04:46

0:03:45

0:03:45

0:00:31

0:00:31

0:06:06

0:06:06

0:34:27

0:34:27

0:03:50

0:03:50

0:06:06

0:06:06

0:05:34

0:05:34

0:05:53

0:05:53

0:07:34

0:07:34

0:02:20

0:02:20

0:00:15

0:00:15

0:06:06

0:06:06

0:01:46

0:01:46

0:06:21

0:06:21

0:00:18

0:00:18

0:08:04

0:08:04