filmov

tv

kWeld DIY Spot Welder - Custom Battery & Enclosure

Показать описание

Hi folks. In this video I show and explain how I built a custom battery & enclosure for my new kWeld DIY spot welder that I purchased from Keenlab. If you're interested, you can download the .stl files for 3d printing the custom enclosure and find the kWeld spot welder and 38120 battery cells at the links below.

Get the files for the custom enclosure here:

Authorized kWeld distributors

Individual 38120 cells:

38120 cells in modules w/ bus bars, screws, holders, etc:

Get the files for the custom enclosure here:

Authorized kWeld distributors

Individual 38120 cells:

38120 cells in modules w/ bus bars, screws, holders, etc:

kWeld DIY Spot Welder - Custom Battery & Enclosure

kWeld - 2000Amps of Battery Spot Welding goodness! ll Assembly & Review

kWeld - The best 18650 spotwelder?

Professional Spot Welds From a DIY Kit?

Spot Welding 18650 DIY Batteries with kWeld

New Spotwelder - Most powerful yet?

Cheap Spot Welder vs K-Weld, 18650

Spot welding fuse wire with the kWeld Spotwelder

cs50 DIY | How To Create kWeld Spot Welder Holder #ESK8builders

K Weld Spot Welder upgrade

kWeld Next level battery spot welder

Lead Acid vs LIPO for PCB Spot Welding

Building Lithium Batteries ? Which Spot Welder is For You?

BATTERY CELL SPOT WELDER. K-WELD.

Kweld Spot Welder For SPIM08HP Lithium Cells

cheap spot welder update and demo (kweld alternative)??

kWeld Next level battery spot welder - 18650 Honeycomb Cell Holder

The Best Spot Welders Are Only $20!

Kweld and LiHV Lipo 3s

kweld battery spot welder vs nutsert

Testing the kWeld Community Spotwelder

kWeld 'next level' battery spot welder - torture test and improvements

How to Spot Weld Nickel Strips onto 18650s - DH30 Portable Spot Welder

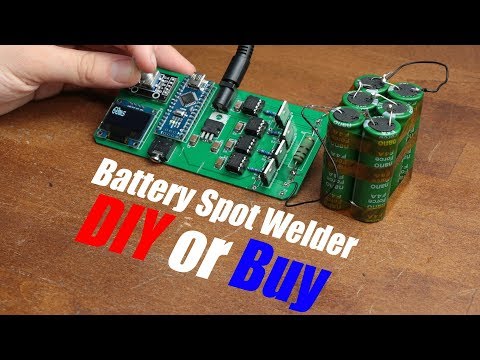

Battery Spot Welder (CD Welder) || DIY or Buy

Комментарии

0:16:30

0:16:30

0:13:13

0:13:13

0:10:56

0:10:56

0:09:30

0:09:30

0:03:21

0:03:21

0:20:07

0:20:07

0:06:33

0:06:33

0:05:11

0:05:11

0:08:27

0:08:27

0:00:59

0:00:59

0:00:06

0:00:06

0:10:46

0:10:46

0:40:10

0:40:10

0:26:59

0:26:59

0:00:53

0:00:53

0:03:14

0:03:14

0:00:28

0:00:28

0:28:55

0:28:55

0:02:17

0:02:17

0:02:49

0:02:49

0:17:36

0:17:36

0:11:48

0:11:48

0:08:31

0:08:31

0:08:03

0:08:03