filmov

tv

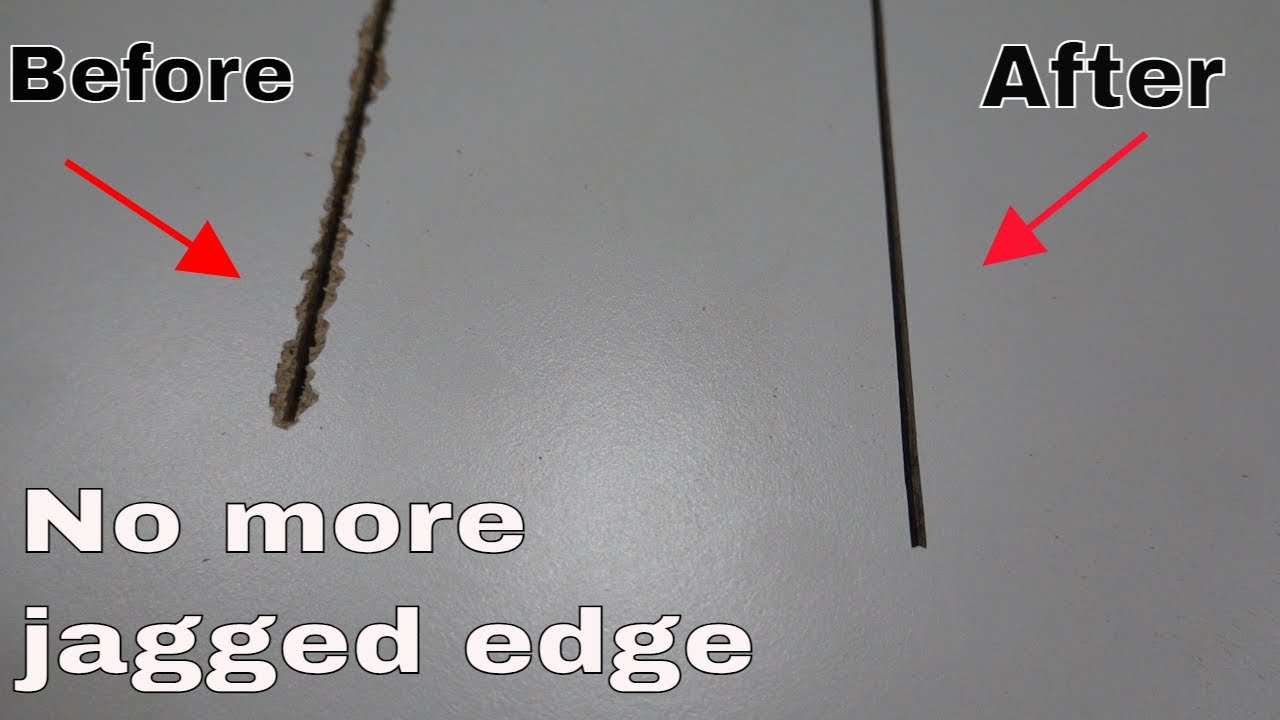

How to make clean cuts with circular saw

Показать описание

This is how to make clean cuts with a circular saw with no tear out, blow out or jagged edges. There are many ideas and theories on how this should be done to get a nice clean finish so I wanted to test them out and show you the results. Next time you want to cut some ply wood, chip board, veneer, laminate or melamine you wont have to experiment on your work as I have done all the hard work for you. For More DFIY and how to videos LIKE COMMENT and SUBSCRIBE.

Your donations help me to keep helping you .....

Amazon product links U.S:

Amazon product links Australia:

#DIY #howto #billshowto

Your donations help me to keep helping you .....

Amazon product links U.S:

Amazon product links Australia:

#DIY #howto #billshowto

How to make clean cuts with circular saw

Few People Know This Jigsaw Trick | How to Cut Clean With Jigsaw

Quick Tips: How to get a Clean Cut with a Jigsaw | Ozito DIY with Andy & Candy

Cricut Hacks for Intricate Vinyl Cuts | How to Get Clean Cuts & Stop Shredding your Vinyl

#1 Jigsaw Blade for CLEAN PLYWOOD CUTS! (Try this Jigsaw Cutting Approach...)

HOW TO CLEAN AND CUT ARTICHOKES

Make clean cuts with a Table Saw - Ozito Tool Tips

How to make clean cuts on wood

Home HiFi Improvement? Cut the Cord!

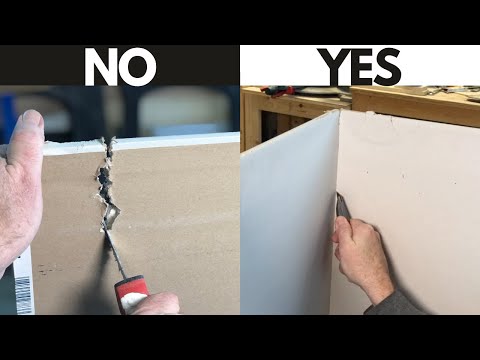

How to Cut Drywall Like a Pro - Quick Clean Cuts

5 Tips For MORE ACCURATE CUTS! (On Any Saw--Make More Accurate Cuts)

How to make clean cuts on your Cricut

No-Snip Metal Flashing Hack - Clean Cuts Made Easy

Use This Blade On Your Jigsaw To Make Clean Cuts ! !

Cut CLEAN edges on a DECK. Contractor shows you how.

Saw Burn Marks? See How to Get Clean Saw Cuts in Wood

Make Clean Cuts - Miter Saw Zero Clearance Fence - Ep 057

How to make a clean, straight cut with a jigsaw

If you want to get clean cuts in DollorTree FoamBoard - WATCH THESE TOP 5 TIPS!

Mastering Chainsaw Techniques: How to Make Clean Cuts

HOW TO CUT A PINEAPPLE | Clean & Delicious

Clean cut on the miter saw

Using A Router To Cut Shapes & Clean Out Holes

Plasma Cutting Basics: How to Get Clean, Straight Cuts

Комментарии

0:13:55

0:13:55

0:03:33

0:03:33

0:00:30

0:00:30

0:04:15

0:04:15

0:05:32

0:05:32

0:01:01

0:01:01

0:00:29

0:00:29

0:00:38

0:00:38

0:05:13

0:05:13

0:01:54

0:01:54

0:05:21

0:05:21

0:04:37

0:04:37

0:01:54

0:01:54

0:00:30

0:00:30

0:06:39

0:06:39

0:06:22

0:06:22

0:02:38

0:02:38

0:01:23

0:01:23

0:04:09

0:04:09

0:00:59

0:00:59

0:02:00

0:02:00

0:01:11

0:01:11

0:05:43

0:05:43

0:09:00

0:09:00