filmov

tv

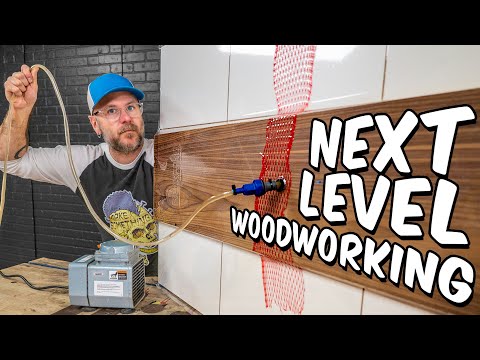

Wood Bending: Vacuum Bag or Jig? | Episode 3

Показать описание

Welcome back to the third episode in a new series of videos where I'm designing, prototyping, and fabricating a new multipurpose piece of furniture for my furniture company, Hoek Home.

Episode 3: In this episode, I try the updated jig that I decided to cut in half last week to see if it is any easier to use. I also try a vacuum-forming bag as an alternative to a jig or mold for the first time! Armed with all the knowledge from the past few weeks of trial and error, I created a second jig with some new additions to make it more user-friendly. I am super excited about how this project turns out, and I am excited to see what you guys think of the finished product! Tune in next week to see the first fully functional prototypes.

This series will utilize hand drawing, 3D modeling, CNC cutting, jig making, bent lamination, and many more techniques. Hopefully, we will see what it takes to create a cool piece of furniture together!

If you have any questions, comments, or ideas about anything I'm doing in the video or things you would like to see covered, please leave your comments below, and I'll be happy to answer them as best as possible!

Check out my furniture brand:

YouTube: @hoek

Get social with me:

Episode 3: In this episode, I try the updated jig that I decided to cut in half last week to see if it is any easier to use. I also try a vacuum-forming bag as an alternative to a jig or mold for the first time! Armed with all the knowledge from the past few weeks of trial and error, I created a second jig with some new additions to make it more user-friendly. I am super excited about how this project turns out, and I am excited to see what you guys think of the finished product! Tune in next week to see the first fully functional prototypes.

This series will utilize hand drawing, 3D modeling, CNC cutting, jig making, bent lamination, and many more techniques. Hopefully, we will see what it takes to create a cool piece of furniture together!

If you have any questions, comments, or ideas about anything I'm doing in the video or things you would like to see covered, please leave your comments below, and I'll be happy to answer them as best as possible!

Check out my furniture brand:

YouTube: @hoek

Get social with me:

Комментарии

0:04:51

0:04:51

0:10:35

0:10:35

0:01:00

0:01:00

0:03:27

0:03:27

0:00:24

0:00:24

0:12:53

0:12:53

0:02:42

0:02:42

0:00:26

0:00:26

0:00:37

0:00:37

0:01:33

0:01:33

0:00:29

0:00:29

0:00:30

0:00:30

0:09:06

0:09:06

0:11:15

0:11:15

0:15:52

0:15:52

0:13:40

0:13:40

0:06:02

0:06:02

0:06:43

0:06:43

0:00:23

0:00:23

0:08:03

0:08:03

0:06:29

0:06:29

0:19:17

0:19:17

0:00:18

0:00:18

0:00:54

0:00:54