filmov

tv

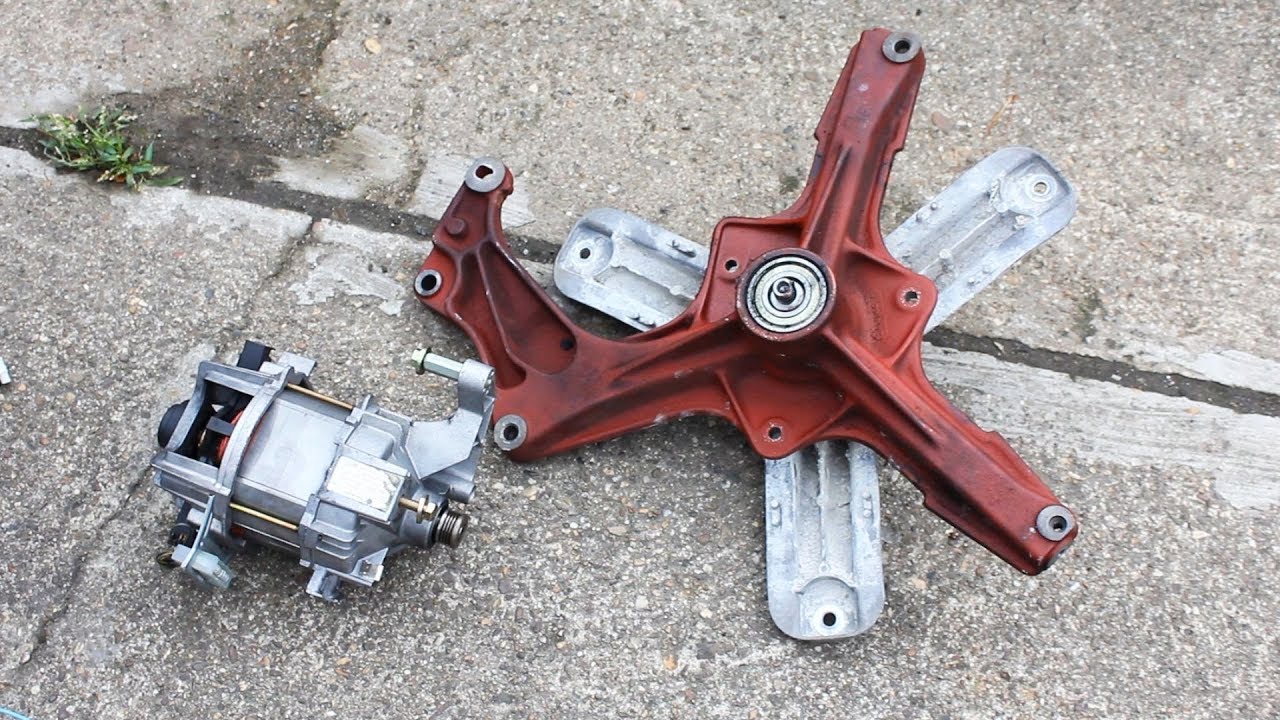

Salvage a Washing Machine Motor + Transmission from a Siemens Washing Machine

Показать описание

My Patreon:

Paypal-Donation Link on the bottom of this site:

Paypal-Donation Link on the bottom of this site:

How to Reuse Washing Machine Motors - (The Simple Way )

Salvage a Washing Machine Motor + Transmission from a Siemens Washing Machine

Things You Can Make With A Washing Machine And Other Salvaged Components : 020

Salvage a Big Electric Motor and Transmission from a Miele Washing Machine

Washing machine motor hack

Inside a Washing Machine Motor: Explanation, Pinout, Teardown AND Experiments

Washing Machine Motor Connections For Your Easy Projects

How to recycle Copper magnet wire from a washing machine motor for free energy projects

Washing Machine Repair Course | Refrigerator Repair Course | Microwave Repair -1 #viralvideo #shorts

Experiments With A Salvaged Washing Machine Motor And Centrifugal Clutch: 017

4 incredible things to do with washing machine motor

Salvaging and Reusing Useful Parts from Dishwashers + EXPERIMENTS

DO NOT THROW THE OLD WASHING MACHINE * awesome idea * NEVER SEEN BEFORE!

Scrapping out a Washing Machine Motor for Copper and Aluminum

Scrapping a Washing Machine - My take on just how profitable it can be!

Scrapping A Washer for Copper Wire & Electric Motor

Washing Machine Motor Scrap Out

DO NOT THROW THE OLD WASHING MACHINE 'NEVER SEEN BEFORE'

220V DC Motor from Washing Machine upto 600W DIY - Salvage Outrunner BLDC Motor (Trash to Treasure)

How To Make Washing Machine Motor 9 Connections

Washing Machine Motor/Stator Testing

Scrapping a Washing Machine for Copper Motor.

How to run a washing machine (universal) motor off a 12v battery

Kenmore/Whirlpool washing machine motor couple failure / replacement! Save $$ Easy fix!!

Комментарии

0:17:58

0:17:58

0:16:16

0:16:16

0:11:52

0:11:52

0:18:45

0:18:45

0:04:21

0:04:21

0:25:22

0:25:22

0:08:09

0:08:09

0:04:55

0:04:55

2:12:56

2:12:56

0:11:57

0:11:57

0:02:13

0:02:13

0:18:01

0:18:01

0:24:35

0:24:35

0:18:53

0:18:53

0:08:46

0:08:46

0:07:23

0:07:23

0:09:47

0:09:47

0:26:41

0:26:41

0:07:06

0:07:06

0:07:41

0:07:41

0:02:39

0:02:39

0:16:20

0:16:20

0:10:05

0:10:05

0:00:53

0:00:53